Industrial Screw Air Compressor: Benefits, Types & Applications

The Powerhouse of Industry: A Comprehensive Guide to Screw Air Compressor:

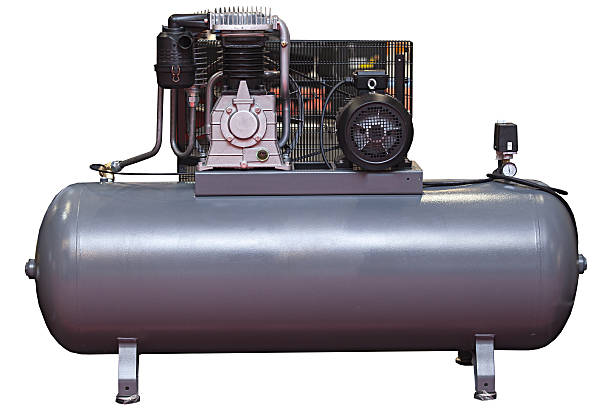

A workhorse in many sectors, the screw air compressor provides a dependable and effective stream of compressed air for a variety of uses. It is essential to comprehend these strong devices to choose and maintain them with knowledge. This thorough guide delves deeply into the world of compressors, examining the many kinds, parts, uses, and advantages.

Demystifying Screw Air Compressors: Exploring the Two Main Types:

The workhorses of the industry, these air compressors provide a consistent stream of compressed air for a variety of uses. However, there are two main configurations in this category, each with advantages and uses of its own:

Oil-injected kind:

The most popular kind of screw air compressor is the oil-injected kind. Oil is used in the compression process for cooling and lubrication. These compressors provide several benefits.

- High Durability and Efficiency:

By reducing wear and friction, oil injection promotes a long life and effective operation.

- Perfect for Continuous Use:

Because of their sturdy construction, they are a good fit for harsh industrial settings where a steady supply of compressed air is needed.

- Cost-effective:

Although regular oil changes are necessary, there aren’t many maintenance requirements overall.

Oil-free Screw Air Compressor:

This kind produces cleaner, contaminant-free air by removing oil from the compression chamber. Because of this, they are the best option for situations where air quality standards are stringent, like:

- Processing of Food and Beverages:

Preventing contamination and guaranteeing product purity.

- Electronics Manufacturing:

It keeps oil mist away from sensitive components.

- Pharmaceutical Production:

They are preserving sterility in the pharmaceutical production process.

Choosing the Right Type:

Your particular demands will determine which oil-injected or oil-free model is best for you. Oil-free is the best option if your application requires pure, contaminant-free air. However, oil-injected compressors frequently perform better for general industrial applications, where durability and cost-effectiveness are important considerations.

Looking Ahead:

We’ll go more into a screw air compressor internal operation and examine the essential parts in the next section. This will offer a thorough comprehension of these potent devices.

Inside the Powerhouse: Unveiling the Key Components of a Screw Air Compressor:

Engineering marvels, these air compressors effectively transform power into a continuous stream of compressed air. But how do these devices operate inside to pull off this feat? Let us examine the essential elements that drive their functioning:

- The Heart: Screw Element:

The central component is the screw element, which consists of two male and female rotors that are intermeshing. The gap between the lobes shrinks as they spin, trapping air between them and compressing it more and more.

- Air Intake Filter:

This filter cleans the entering air stream of impurities, dust, and debris, serving as the first line of defense. For proper functioning, it is essential to shield the interior components from deterioration.

- Using an air cooler:

Heat is produced during compression. The air cooler lowers the air temperature by using either water or air after the first compression step. The compressed air is further cooled by the aftercooler, which also eliminates moisture that condenses as a result of the temperature reduction.

- Oil Management (only for versions with oil injection):

This part keeps compressed air and the oil used for cooling and lubricating apart. After that, the oil is recycled back into the system to keep it running. Prevents accumulation and preserves peak performance by automatically clearing the system of accumulated condensate and oil, if applicable.

- Powering the Machine:

The motor supplies the required power to turn the screw element. Internal combustion engines are used in certain versions, although electric motors are the most popular. The screw element receives power from the motor through the drive system. This can be accomplished via a direct-driven connection or belts.

Keeping Things Under Control: Panel of Control

This serves as the compressor’s brain, continually monitoring and controlling vital elements including oil level, temperature, and pressure. Moreover, it manages safety measures, shutdown, and startup of the machine. These parts ensure a screw air compressor operates effectively and dependably by coordinating with one another. Gaining an appreciation of these industrial workhorses’ strength and intricacy begins with an understanding of their responsibilities.

From Factories to Fabrication: The Diverse Applications of Screw Air Compressors

Screw air compressor is widely used in many different sectors due to their adaptability. Numerous uses are made possible by their capacity to provide a steady and controlled stream of compressed air, including:

- Manufacturing Powerhouse:

Screw compressors are necessary to run pneumatic equipment like drills, sanders, and riveters in assembly lines, fabrication shops, and production facilities. For jobs like material handling, component polishing, and product assembly, these instruments are indispensable.

- Essential Construction Crew:

Compressed air powers tools like drills, sandblasters, and nail guns used in construction projects. Screw compressors guarantee an uninterrupted supply of these instruments, promoting effective surface preparation, fastening, and framing.

- Automotive Industry Foundation:

Body shops use screw compressors to power impact wrenches, spray paint, and inflate tires. They are also essential for using other workshop tools and diagnostic equipment.

- Food and Drink Champion (Models without oil):

Oil-free screw compressors are useful in situations that require air free of contaminants. They preserve the hygiene and integrity of the product by supplying clean air for operations like bottling equipment, fermentation, and packing lines.

- Woodworking Workshop Partner:

Sanders, nail guns, and other woodworking equipment are powered by screw compressors. For jobs like cabinetry, wood finishing, and furniture construction, their steady air pressure guarantees precise control and seamless operation.

Screw air compressors play vital roles:

- Oil and Gas Industry:

Compressed air is used for a variety of jobs in drilling, exploration, and pipeline maintenance.

- Mining Operations:

Compressed air is necessary for the effective functioning of rock drills, breakers, and other excavation machinery.

- Projects using sandblasting:

Abrasive material is propelled by screw compressors to clean and prepare surfaces in a variety of industries.

- Painting Applications:

Compressed air is frequently necessary for the effective operation of spray guns and other painting equipment.

The wide range of uses for these compressors demonstrates their versatility and vital role in supplying energy to several industrial processes. We’ll go into more detail about the many advantages that air compressors provide in the next section.

Why Choose LEIYAO Compressor?

A name to keep an eye on is LEIYAO Compressor. We are a rising force in the industry, providing competitive screw air compressor solutions at affordable costs. Our brand reputation still be growing, consumers on a tight budget should give them some thought. This business has extensive skills in testing, machining, welding, assembly, performance analysis, and technical design. Outfitted with many state-of-the-art industrial processing machinery, it creates a solid foundation for producing high-end gas compressors.

The Winning Formula: Unveiling the Advantages of Screw Air Compressors

Reliability, economy, and efficiency are critical in today’s cutthroat industrial environment. Screw air compressor is a successful combination for companies in a variety of industries because they offer a compelling set of benefits.

- Designed to Last: Dependability and Sturdiness:

Their extended service life and dependable operation are a result of their sturdy construction and few moving components. Screw compressors minimize downtime and maintenance requirements since they can survive harsh conditions and continuous operation.

- Driving force: High Efficiency:

Screw compressors with sophisticated technical characteristics use less energy while compressing a material. Lower running expenses result from this, which is a big plus in the energy-conscious world of today.

- Calm & Stillness: Reduce the Volume of Noise:

Screw air compressors operate at far lower noise levels than their piston equivalents. This helps businesses comply with noise restrictions and gives employees a more pleasant place to work.

- Low Need for Maintenance:

Screw air compressors require less maintenance because of their straightforward design. Their total maintenance requirements are lower than those of other compressor types, even if routine inspections and oil changes (for units that use oil injection) are required.

- A Breath of Fresh Air (Models without oil):

One clear benefit of oil-less screw compressors is the air they produce is pure and devoid of pollutants. This makes them perfect for uses including the processing of food and beverages, the making of electronics, and the manufacturing of pharmaceuticals, where even a small amount of oil residue might be harmful.

Beyond the Core Benefits:

Additionally, screw air compressors have the following benefits:

- Scalability:

To satisfy their unique compressed air needs, businesses can select from a broad range of sizes and capacities.

- Ease of Use:

Automated features and control panels make maintenance and operation simpler.

- Safety Features:

In the event of overheating or pressure fluctuations, modern screw compressors are outfitted with automated shutdown mechanisms.

These compressors establish themselves as a potent and affordable choice for companies looking for a stable source of compressed air by combining efficiency, dependability, and a host of other advantages.

Conclusion:

LEIYAO Compressor is a rising force in the industry, providing competitive compressor solutions. Even if they might not be well-known just yet, they are nonetheless worthwhile to take into account, particularly for consumers on a tight budget looking for perhaps affordable solutions.