The Ultimate Guide to Reciprocating Compressor Manufacturers: functions, Applications

Understanding Reciprocating Compressors by Functionality:

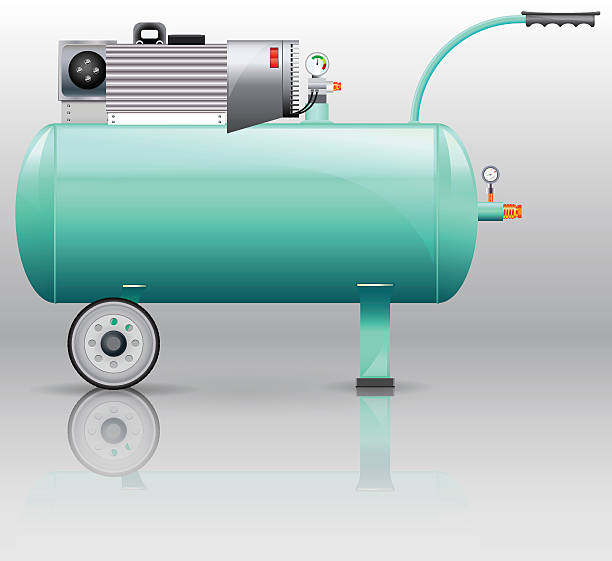

Reciprocating Compressor Manufacturers can be configured in a variety of ways to meet different requirements. The reciprocating compressor, the industrial workhorse, is essential to the compressed air industry. These devices compress air using a piston-driven mechanism, which powers a wide range of uses.

Below is a summary of some of the main features:

- High-Pressure Reciprocating Compressors:

Designed for demanding applications, these compressors reach pressures of more than 100 bar (1450 psi). They are employed in high-pressure testing, gas injection applications, and industrial operations.

- Low-Pressure Reciprocating Compressors:

These compressors are frequently used for paint spraying, tire inflation, and powering pneumatic equipment. They are perfect for applications needing moderate pressure (up to 10 bar or 145 psi).

- Industrial reciprocating compressors:

These durable compressors are used in manufacturing plants, building sites, and workshops. They are made to run continuously under harsh conditions.

- Portable Reciprocating Compressors:

These small compressors are ideal for on-site tasks including equipment maintenance, roadside assistance, and building projects since they are portable and flexible.

- Oil-Free Reciprocating Compressors:

These compressors remove the possibility of oil contamination in the compressed air output, which is essential for applications needing pure, contaminant-free air. They are employed in the production of electronics, in the food and beverage sector, and medicinal applications.

- Silent Reciprocating Compressors:

In some settings, minimizing noise is of utmost importance. Because these compressors include noise-dampening qualities, they may be used in places where noise is an issue, such as workplaces, homes, and hospitals.

Exploring Excellence: LEiYAO Compressors – A Benchmark in Reciprocating Compressor Manufacturing

Our compressor is one such enduring name in the reciprocating compressor industry. Being a leader in compressor production, we have a reputation for pushing limits and an unwavering dedication to perfection. To learn more about choosing the best reciprocating compressor, check out our thorough buyer’s guide on our website. To locate a distributor in your area, go to the website of LEIYAO Compressors (or the manufacturer of your choice). They may provide the choice to make purchases directly from their website.

Fundamental Engineering Ingenuity:

Our Compressors are based on an engineering excellence culture. The business carefully and precisely crafts each compressor using state-of-the-art technology and a team of seasoned workers. Every stage of the manufacturing process, from design to production, is driven by an unrelenting quest for excellence.

A Wide Range of Products:

With a wide range of products to choose from, our compressors serve a wide range of industrial applications. When it comes to providing power to pneumatic equipment in a manufacturing plant or preserving ideal pressure in HVAC systems, our compressors offer unmatched effectiveness and output. Customers may choose from a variety of LEiYAO variations that are specifically designed to satisfy their demands.

Superior Quality Assurance:

With its steadfast dedication to quality, our compressors stand strong in a sector where dependability is non-negotiable. Strict quality control procedures are implemented throughout the whole production process to guarantee that every compressor satisfies the highest requirements for longevity and performance. Our commitment to providing products that surpass expectations is demonstrated by its strict testing procedures and painstaking attention to detail.

Customer-Centric Approach:

Our steadfast emphasis on client satisfaction is the cornerstone of its success. LEiYAO cultivates long-lasting partnerships based on trust and dependability by giving priority to client demands and feedback. LEiYAO goes above and above to make sure that clients receive unmatched value at every touchpoint, whether it is through prompt technical assistance or the provision of tailored solutions.

Taking Up Sustainability to Create a Greener Future:

In the face of global acceptance of sustainability as the cornerstone of industrial advancement, our compressors are unwavering in their dedication to environmental care. We reduce its carbon footprint and maximize energy efficiency by utilizing eco-friendly technology and optimizing resource consumption. For future generations, we aim to build a cleaner, greener future via sustainable practices and green projects.

Applications of Reciprocating Compressors:

Reciprocal compressors are quite versatile and are used in many different sectors. Here are a few well-known uses:

Air Conditioning:

The main part of many air conditioning systems, reciprocating compressors is in charge of moving refrigerant around the system.

Automobile:

Reciprocal compressors are necessary for a variety of automobile services and maintenance tasks, from tire inflation to the operation of pneumatic equipment in workshops.

Chemical Processing:

These compressors are used in chemical facilities for several purposes, such as instrument air supply, gas compression for reactions, and chemical transfer.

Food and Beverage Industry:

In the manufacture of food and beverages, maintaining constant air pressure is essential. Clean air is ensured for procedures including bottling, fermentation, and packing using oil-free reciprocating compressors.

Oil and Gas Industry:

In refineries, reciprocating compressors are used for instrument air supply, natural gas reinjection into reservoirs, and wellhead gas collecting.

Finding the Right Reciprocating Compressor Manufacturer:

With a plethora of reciprocating compressor manufacturers globally, selecting the right partner is essential. Select a manufacturer who has a track record of excellence and dependability. Seek out well-established businesses with a track record of creativity and client happiness. One well-known maker of high-quality reciprocating compressors is LEIYAO Compressors. Here are some things to think about:

Experience and Reputation:

Select a company with a solid track record of dependability and quality. Seek out well-established businesses with a track record of creativity and client happiness.

Product Range:

Verify that the manufacturer has compressors in stock that can satisfy your unique demands for flow and pressure. Think about things like mobility, noise levels, and, if necessary, oil-free solutions.

Post-purchase Assistance:

A strong network of after-sales assistance is essential for upkeep, repairs, and easy access to replacement components.

Conclusion:

Reciprocating Compressor Manufacturers, LEiYAO Compressors is a leader in compressor production, setting new standards for quality. One compressor at a time, LEiYAO is reshaping the industry with its unwavering commitment to quality, innovation, and customer satisfaction. The reputation for quality keeps growing as businesses all over the world commit their operations to the dependability and efficiency of our compressors, creating new benchmarks for the next generations.