The Critical Role of Helium Compressor in Various Industries

Introduction

Helium Compressor, an element often associated with balloons and funny voices, plays a far more crucial role in various industries than most people realize. This colorless, odorless gas is not only used for entertainment but also serves as a vital component in a multitude of applications, from healthcare to scientific research. One of the key technologies that make the use of helium feasible in these industries is the helium compressor. In this comprehensive guide, we will delve into the world of helium compressors, exploring their definition, functions, applications, types, selection criteria, maintenance, safety measures, and future trends.

What is a Helium Compressor?

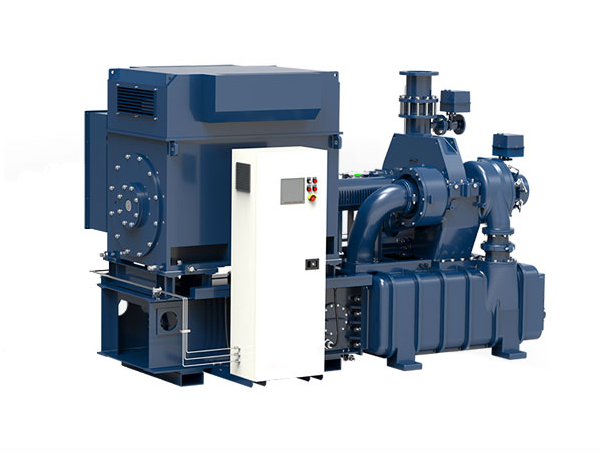

A helium compressor is a specialized mechanical device designed to pressurize and compress helium gas. Its primary purpose is to increase the pressure of helium, making it suitable for various applications where high-pressure helium is required. Unlike the balloons we commonly associate with helium, these compressors deal with large quantities of the gas in a controlled and efficient manner.

Helium compressors operate based on the principles of thermodynamics and fluid mechanics. They take in low-pressure helium gas and compress it using a combination of pistons, valves, and heat exchangers. The compression process increases the gas’s pressure, making it ready for use in a wide range of industrial applications.

Applications of Helium Compressors

Helium compressors are indispensable in several industries and sectors. These include but are not limited to:

- Healthcare: In Magnetic Resonance Imaging (MRI) machines, where high-pressure helium is required to cool superconducting magnets.

- Cryogenic Research: For liquefying helium for cryogenic applications and experiments.

- Aerospace: In testing and launching rockets, as well as pressurizing fuel tanks.

- Nuclear Energy: For cooling and pressurizing nuclear reactors.

- Scientific Research: In laboratories conducting experiments with low-temperature physics.

- Industrial Gas Production: To compress helium for distribution and use in various industrial processes.

Helium compressors find specific applications in critical areas such as:

- MRI Machines: Helium compressors are essential for maintaining the superconducting state of magnets in MRI machines, enabling high-resolution imaging in healthcare.

- Cryogenic Experiments: Researchers use helium compressors to achieve ultra-low temperatures for studying materials’ properties at extreme conditions.

- Aerospace Testing: Helium compressors are used to pressurize rocket engines and simulate space conditions during testing.

- Particle Accelerators: In laboratories, helium compressors are integral to cooling components of particle accelerators.

- Gas Chromatography: Used to provide high-purity helium for gas chromatography analysis in chemistry laboratories.

Types of Helium Compressors

Helium compressors come in various types, each tailored to specific applications:

- Oil-Free Compressors: These compressors eliminate the risk of oil contamination in helium, making them ideal for applications where pure, oil-free helium is essential.

- Cryogenic Compressors: Designed to handle extremely low temperatures, these compressors are used in cryogenic research and applications.

- High-Pressure Compressors: High-pressure helium compressors are employed in industries where compressed helium at elevated pressures is required, such as aerospace and nuclear energy.

Oil-free compressors ensure the purity of helium, making them suitable for applications like MRI machines, where any contamination can affect results. Cryogenic compressors are designed to handle extremely low temperatures without malfunctioning, while high-pressure compressors are robust and reliable for heavy-duty industrial applications.

How to Choose the Right Helium Compressor

Choosing the right helium compressor is critical to ensure efficiency and safety in your application. Consider the following factors:

- Flow Rate and Capacity: Determine the required flow rate and capacity based on the volume of helium needed for your specific application.

- Pressure Requirements: Assess the pressure levels required for your application and select a compressor that can deliver it reliably.

- Energy Efficiency: Look for compressors that are energy-efficient to reduce operating costs.

- Maintenance and Reliability: Consider the maintenance requirements and reliability of the compressor to minimize downtime.

Consult with experts in the field, review technical specifications, and consider your long-term needs when choosing a helium compressor. It’s essential to match the compressor’s capabilities with the demands of your application to achieve optimal results.

Maintenance and Care of Helium Compressor

Regular maintenance is paramount to ensure the continued efficiency and safety of helium compressors. Neglecting maintenance can lead to decreased performance, increased energy consumption, and even safety hazards.

Maintenance tasks for helium compressors may include cleaning, lubrication, inspection of valves and seals, and monitoring of pressure and temperature levels. Establishing a maintenance schedule and adhering to it is crucial to prevent unexpected breakdowns.

Helium Compressor Safety

Safety is of utmost importance when working with helium compressors, as helium gas can be hazardous if mishandled. Safety precautions may include:

- Proper Training: Ensure that operators are trained in the safe operation of helium compressors.

- Ventilation: Provide adequate ventilation in compressor rooms to prevent the accumulation of helium gas.

- Leak Detection: Implement systems for detecting and addressing helium leaks promptly.

- Emergency Procedures: Develop and communicate clear emergency procedures for dealing with helium-related incidents.

In addition to compressor safety, it’s crucial to handle helium gas itself with care. This includes proper storage, transportation, and disposal procedures to minimize risks.

Future Trends in Helium Compression Technology

The field of helium compression technology is ever-evolving, driven by the need for greater efficiency and sustainability. Emerging trends include the development of more energy-efficient compressors, advancements in cryogenic compression technology, and innovations in materials and design.

These advancements in helium compression technology have the potential to revolutionize various industries. They can lead to reduced energy consumption, lower operating costs, and expanded possibilities in scientific research and healthcare, among others.

Conclusion

In conclusion, helium compressors are unsung heroes in numerous industries, facilitating applications that range from cutting-edge healthcare to groundbreaking scientific research. Understanding their importance, types, selection criteria, maintenance, and safety measures is crucial for harnessing the full potential of helium gas. As technology continues to evolve, the future promises even more efficient and sustainable helium compression solutions, paving the way for innovation and progress in the industries they serve. Let us embrace this technology and continue to explore its possibilities to unlock a world of opportunities.