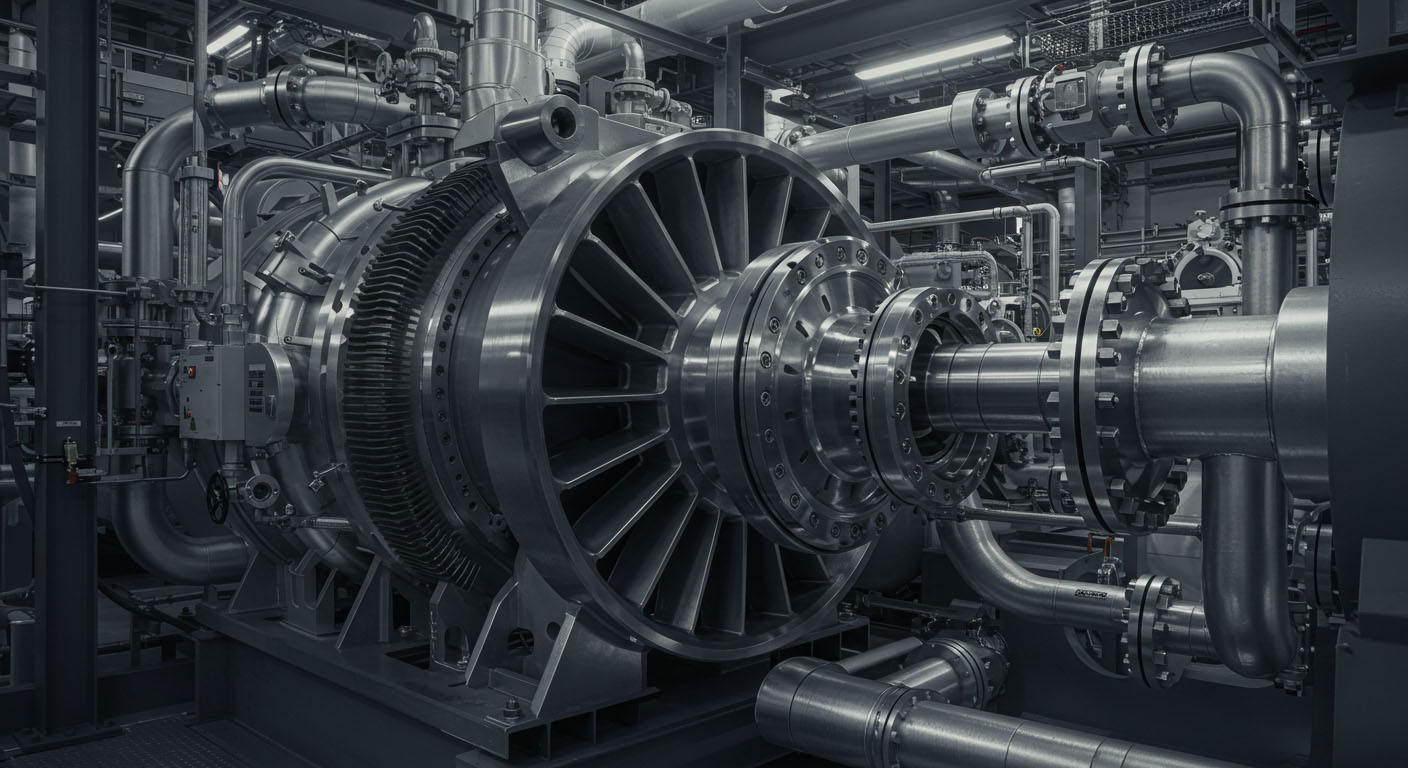

The Best Hydrogen Sulfide Screw Compressor for Oil & Gas Industry

A Definitive Guide to Hydrogen Sulfide Screw Compressor:

H₂S is another naturally occurring gas that is freely available in the environment mainly in the shale oil and gas industry. It is toxic and corrosive; therefore, it is one of the most difficult gases to manage. Meet the hydrogen sulfide screw compressor, a fairly essential tool that will allow the compression of this dangerous gas without risking lives in the process. Now, let’s take a closer look at the details and view what you have to know about these compressors: the benefits, importance, and types of industries that use them.

What Does Hydrogen Sulfide Screw Compressor Mean?

A screw compressor on the other hand is special equipment that is employed specifically for compressing hydrogen sulfide gas. These compressors are mainly built for sour gas which refers to the natural or petroleum gas containing a high proportion of H₂S. H2S being toxic and corrosive, these compressors are designed and manufactured keeping in view robust technologies and materials.

Why is Hydrogen Sulfide Compression Important?

The use of hydrogen sulfide compression is important in the upstream part of the oil and gas business. This gas is predominantly identified in natural gas and petroleum fields, and therefore its safe management is vital for the conservation of the environment and lives of people. The method of compounding hydrogen sulfide is recommended because it helps in the transportation, storage and utilization of the product after passing through the necessary changes such as the production of sulfur.

What Applications of Hydrogen Sulfide Screw Compressors?

Hydrogen sulfide screw compressor is applied in the industries that employ sour gas handling as a central process. Here are some of the key applications:

Oil and Gas Industry: This is achievable through the removal of hydrogen sulfide from the natural gas and petroleum processing systems and then compressing the remaining substance.

Refineries: Sour gas and its management, especially in the context of refining, and measures of operating safely and efficiently.

Petrochemical Plants: To use it in the manufacture of chemicals and other processes the hydrogen sulfide needs to be compressed.

Sulfur Recovery Units (SRUs): These compressors are very essential in the process of helping to recover sulphur from hydrogen sulphide gas.

Gas Processing Plants: Addressing hydrogen sulfide in natural gas processing thus allowing the substance to be transported and stored safely.

Leading Screw Compressor for Hydrogen Sulfide Made by LEiYAO:

The LEiYAO industrial gas compressor is famous in the market, particularly in the hydrogen sulfide (H₂S) screw compressor. These compressors are used to address the dynamic operational features for compressing hydrogen sulfide which is a very toxic as well as corrosive gas in the oil and gas sector. Below are some of the top features and benefits of the LEiYAO hydrogen sulfide screw compressor:

The Important Characteristics:

Advanced Rotary Screw Technology: we offered a compressor that employs the advanced rotary screw technology that helps in compressing the gases with optimum efficiency and energy availability. It has been known to be very effective, especially in unforgiving terrain conditions and the devices are long lasting.

Corrosion-Resistant Materials: The structures of screw compressors of LEiYAO are internally developed with materials that are of high standard and selected for their resistance to corrosive hydrogen sulfide. This helps to guarantee that the compressor is not corroded by hydrogen sulfide so that its maintenance costs and periods are not high.

High Efficiency: Our compressors are designed to achieve the highest levels of performance, with reliable compression ratio and flow rates that drive maximum output/head with minimal power requirement. This makes them very suitable for use in any power application that is needed and emphasizes the efficient use of power.

Customizable Specifications: We build several types to provide a specific industry’s requirements. Whether it is the discharge pressure, flow rate or inlet temperature, LEiYAO is in a position to design its compressors to fit the specific needs of your company.

Compliance with Safety Standards:

It is important to note that the safety of workers and the environment is core to the design of the LEiYAO compressor. Our machines also conform to the standard safety requirements in handling hazardous and toxic gas in all working environment.

The Role of Hydrogen Sulfide Screw Compressors in the Oil and Gas Industry:

Hydrogen sulfide screw compressor is very important in the oil and gas industry especially where hydrogen sulfide is produced. These compressors are utilised for operating sour gas that is usually encountered in oil and gas production processes. Hydrogen sulfide must be compressed to avoid the dangers which it presents to the environment and the people.

Key Functions in the Oil and Gas Industry:

• Gas Gathering: Currently most hydrogen sulfide is transported as a gas from the wellhead to processing facilities but this compressing of the gas makes this to be easier.

• Processing: To decrease the levels of hydrogen sulphide in the natural gas and to increase its functionality and safe transportation and usage.

• Sulfur Recovery: Converting hydrogen sulfide into sulfur that is useful in many industries as a product.

Hydrogen Sulfide Screw Compressors Maintenance and Care:

Adherence to maintenance practices is imperative for the two hydrogen sulfide screw compressor types to serve their expected level of efficiency for a longer period. Here are some maintenance tips:

• Regular Inspections: The seals, as well as other materials and components of the compressor, should be inspected as often as possible to identify cases of wear or corrosion.

• Seal Replacement: It is therefore important to replace the seals as often as possible to avoid emissions of gas and also to ensure that the compressor is energy efficient.

• Corrosion Control: In addition apply anti-corrosion measures to prevent the compressor from being corroded by hydrogen sulfide.

• System Monitoring: Implement surveillance mechanisms that will enable you to monitor the performance of the compressor and alert you in case it develops some severe problems.

Conclusion:

LEiYAO hydrogen sulfide screw compressor stand out in the market for its advanced technology, durability, and safety features. Whether you are in the oil and gas industry, a petrochemical plant, or a sulfur recovery unit, we provide reliable and efficient solutions for handling hydrogen sulfide gas. Their commitment to quality and innovation makes them a top choice for companies looking to invest in safe and efficient gas compression technology.

Read more: Learn More About Our Gas Compression Solutions, you can visit their official website.