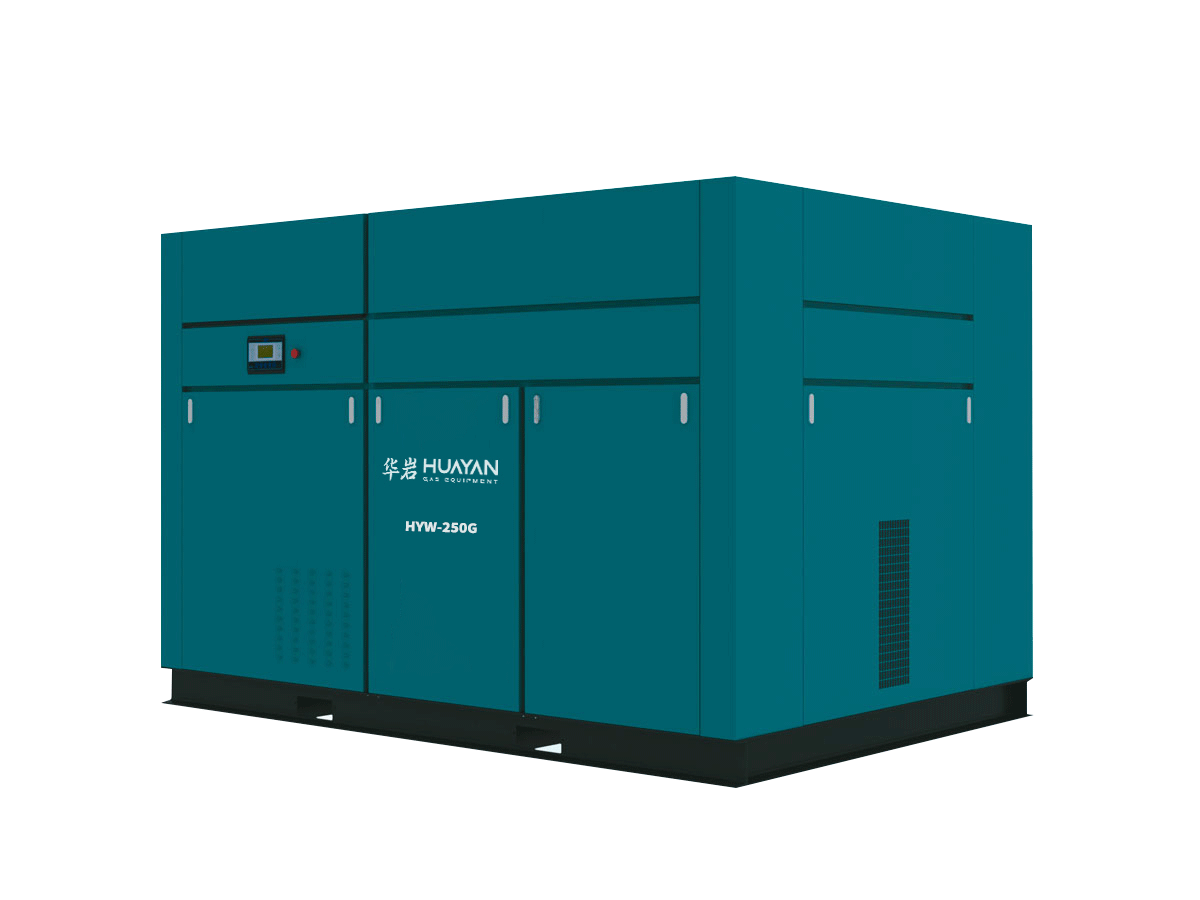

Low Noise Rotary Screw Air Compressor For Industry

Low Noise Rotary Screw Air Compressor For Industry

- Power 5.5-75kw

- Voltage 380V 3phase

- Working Pressure 7-10bar

- Flow 0.52~13.50 M³/min

- Cooling Method Airing cooling / Water cooling

Description

Introducing our state-of-the-art Low Noise Rotary Screw Air Compressor, designed to revolutionize the way industries harness compressed air. This powerful and reliable compressor is engineered to deliver high-performance results without compromising tranquillity. Say goodbye to the days of noisy and disruptive air compressors – our solution is the perfect harmony of power and peace.

Features & Characteristics:

Our Low Noise Rotary Screw Air Compressor features a large-rotor low noise master system, 3-phase asynchronous electric motors, a 5-inch intelligent control system, and innovative design elements for efficient, quiet, and sustainable industrial air compression.

- Whisper-Quiet Operation: One of the standout features of our Low Noise Screw Air Compressor is its exceptionally low noise level. No more distractions, no more disruptions – just the hum of productivity.

- Highly Efficient Rotary Screw Technology: The heart of this compressor lies in its cutting-edge rotary screw technology. Unlike traditional piston compressors, rotary screw compressors offer superior efficiency and reliability. The continuous, smooth operation results in lower energy consumption.

- Compact and Space-Saving Design: Our Low Noise Screw Air Compressor is engineered with a compact design. This space-saving feature does not compromise on performance; instead, it enhances the versatility of the compressors.

- User-Friendly Control Panel: Ease of use is paramount in our design philosophy. The user-friendly control panel of our compressor allows for effortless operation and monitoring. Adjusting settings, checking performance metrics, and ensuring optimal output have never been simpler. This intuitive interface empowers operators to maximize the compressor’s potential with minimal effort.

- Built for Durability: Industrial environments demand robust and durable equipment, and our Low Noise Screw Air Compressor rises to the occasion. Its longevity ensures a solid return on investment, making it a wise choice for businesses focused on sustainability and cost-effectiveness.

Main Structure: Low Noise Rotary Screw Air Compressor

Our Low Noise Rotary Screw Air Compressor boasts a revolutionary main structure.

- It is powered by 3-phase asynchronous electric motors with F-class insulation and features a large-rotor low-noise master system for quiet operation.

- The 5-inch intelligent control system ensures user-friendly operation.

- This compressor combines innovation and efficiency with an enclosed air intake and exhaust design for automatic energy-saving control, an external oil tank for easy maintenance, and quick steel pipe connection technology for efficient installation.

- The large coolers with an upside wind design enhance heat dissipation. Elevate your industrial air compression standards with this cutting-edge, high-performance solution.

Applications: Low Noise Rotary Screw Air Compressor

Our Low Noise Rotary Screw Air Compressor finds versatile applications, from powering pneumatic tools in manufacturing and automotive workshops to contributing precision in the medical and electronics industries, creating a quiet and efficient work environment across diverse sectors.

- Electronics Manufacturing: Contributing to the precision required in electronic assembly processes, including PCB manufacturing and assembly line operations. Ensuring a clean and quiet working environment for delicate electronic components.

- Food and Beverage Processing: Supporting pneumatic systems in food processing equipment, such as packaging machinery and conveyor systems. Maintaining a hygienic and quiet environment in food and beverage production to meet industry standards.

- Mining Operations: Power pneumatic tools for mining activities, including rock drills and compressed air systems for ventilation. Operating efficiently in rugged and demanding mining environments with a focus on durability and reliability.

- Energy Sector: Supporting various compressed air applications in the energy industry, including power plant operations and maintenance. Ensuring reliable and low-noise operation in power generation and distribution facilities for optimal efficiency.