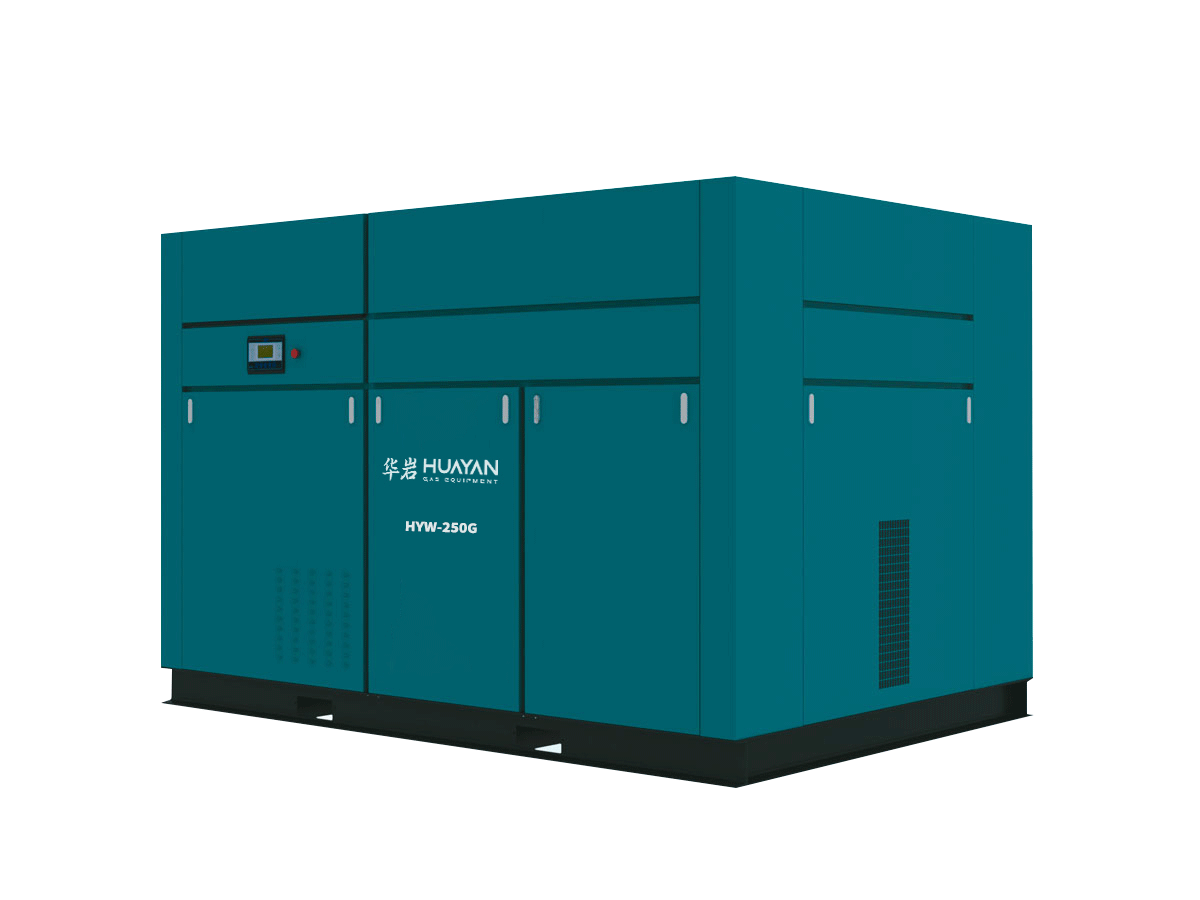

Integrated Screw Air Compressor

Integrated Screw Air Compressor

- Power 5.5~37 KW

- Voltage 380V 3phase

- Working Pressure 7-13bar

- Flow 0.52~6.50 M³/min

- Fuel Tank Capacity 65-400L

- Cooling Method Airing cooling / Water cooling

Get Free Quote

Description

An Integrate Type Screw Air Compressor typically refers to a compressor system that incorporates various components into a single unit. This integration can include the compressor unit, air receiver tank, dryer, filters, and sometimes the control panel. Integrating these components aims to create a compact and efficient system that is easier to install and operate. These systems are suitable for users who need a complete and ready-to-use compressed air solution without having to source and assemble individual components.

Features & Characteristics:

Here are the key features that make this compressor outstanding:

- Air Quality Optimization: The integrated system enhances air quality to meet the specific needs of various industrial processes.

- Space-Saving Design: The compact compressor system saves space in industrial settings.

- Complete System: The integrated design eliminates the need for additional drying systems and the installation cost of connecting pipelines.

- Ease of Use: The system is user-friendly, flexible, and lightweight. Users can access high-quality compressed air when connected to the power supply.

- Integrated Electric Control Cabinet: The control cabinet combines the compression and drying systems, improving efficiency. This centralized control sets it apart from similar products.

- Modular Installation: It supports modular installation in production lines, enhancing the integrity of the overall production system.

- Aesthetic Design: The compressor boasts a beautiful appearance, reliable performance, and excellent economic efficiency.

Main Structure: Integrate Type Screw Air Compressor

- Piston Compressor: Generates compressed air using a piston-cylinder arrangement.

- Refrigeration Condenser: Cools compressed air, preventing system overheating.

- Precise Filter: Enhances air quality by removing impurities and moisture.

- Storage Tank: Acts as a reservoir, ensuring a stable and continuous air supply.

- Easy Installation: A one-piece structure streamlines installation.

- Simplicity of Use: Centralized control for user-friendly operation.

- Mobile Portability: Compact design allows easy movement within a facility or between job sites.

Applications: Integrate Type Screw Air Compressor

Integrated-type screw air compressor has a lot of applications that make it versatile for users.

- Lubrication systems in machine tool machinery: Compressed air is utilized in the pneumatic systems responsible for lubricating various components in machine tools. This ensures smooth operation and extends the life of the machinery.

- Electronic Industry: Integrated screw air compressors are essential for maintaining controlled environments in semiconductor manufacturing. They contribute to the inflation of packaging materials and provide the necessary compressed air for vacuum moulding processes used in electronic component fabrication.

- Pharmaceutical Industry: Integrated screw air compressors contribute to pneumatic control systems in pharmaceutical manufacturing. The power valves, actuators, and other pneumatic components precisely control processes during drug production.

- Agrohorticultural Chemicals: In agriculture, integrated screw air compressors are employed for the pneumatic application of fertilizers. This ensures an efficient and uniform distribution of fertilizers in orchards and fields, contributing to crop health and growth.

- Building Decoration Material Industry: Integrated screw air compressors power pneumatic sanding tools used in the production of gypsum board. They contribute to the sanding process’s efficiency and precision, enhancing the building decoration materials’ quality.

| Integgrate type screw air compressor technical parameters | ||||||||||||

| Model | Working pressure (Mpa) | Dryer capacity(m3/min) | Filter Filtration(um/ppm) | (Kw) | Tank volume (L) | noise(dB) | Air outlet pipe diamete r(inch) |

weigtht(Kg) | Dimension(mm) | |||

| 0.75 | 0.85 | 1 | 1.3 | |||||||||

| Exhaust volume(m3/min) | ||||||||||||

| HY-5SAT | 0.86 | 0.75 | 0.66 | 0.52 | 1.2 | 0.01 | 5.5 | 200 | 60±3 | G1″ | 450 | 1686*800*1285 |

| HY-7SAT | 1.23 | 1.16 | 1.05 | 0.89 | 1.2 | 0.01 | 7.5 | 200 | 60±3 | G1″ | 470 | 1686*800*1285 |

| HY-11SAT | 1.8 | 1.68 | 1.47 | 1.25 | 2.4 | 0.01 | 11 | 250 | 62±3 | G1″ | 600 | 1900*850*1450 |

| HY-15SAT | 2.25 | 2 | 1.9 | 1.5 | 2.6 | 0.01 | 15 | 500 | 62±3 | G1″ | 750 | 2150*1000*1700 |

| HY-18SAT | 3.25 | 3 | 2.7 | 2.3 | 3.8 | 0.01 | 18.5 | 500 | 64±3 | G1″ | 850 | 2150*1000*1700 |

| HY-22SAT | 3.7 | 3.55 | 3.2 | 2.8 | 3.8 | 0.01 | 22 | 550 | 64±3 | G1 1/2″ | 900 | 2250*1050*1850 |

| HY-30SAT | 5.2 | 5 | 4.25 | 3.75 | 6.5 | 0.01 | 30 | 550 | 64±3 | G1 1/2″ | 950 | 2250*1050*1850 |

| HY-37SAT | 6.5 | 6.15 | 5.6 | 4.6 | 6.5 | 0.01 | 37 | 550 | 64±3 | G1 1/2″ | 1100 | 2300*1150*1950 |