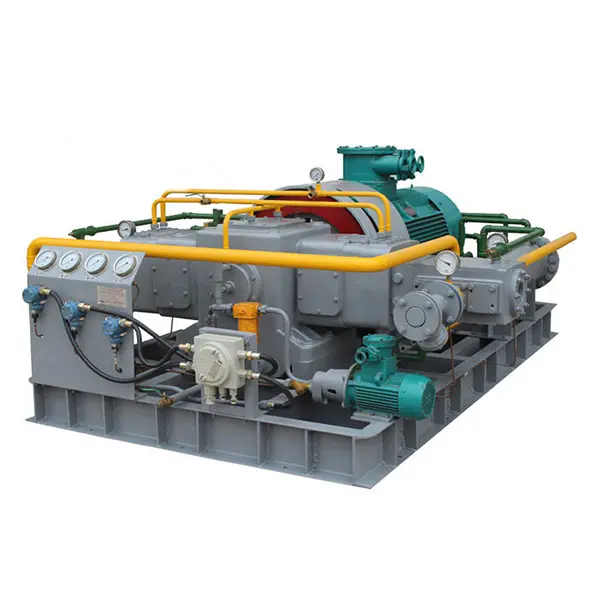

Industry Compressor For Loading And Unloading

Industry Compressor For Loading And Unloading

- Brand: Huayan Gas

- Place of Origin: China,Vietnam

- Compressor structure: Piston Compressor

- Volume flow 3NM3/hour~1000NM3/hour (customized)

- Voltage: 380V/50Hz (customized)

- Maximum outlet pressure: 100MPa (customized)

Description

A Loading and Unloading Compressor is a specialized piece of equipment designed for efficiently handling gases, particularly in industries where loading and unloading various compressed gases are critical. These compressors are specifically engineered to fill or unload gas from storage tanks, pipelines, or other containers.

Features & Characteristics:

Here are features that make our Loading and Unloading Compressor the ultimate choice for your industrial needs:

- Adaptive Control: The ability to adjust the compressor’s operation to match the demand for compressed gas, optimizing efficiency and energy consumption.

- Comprehensive Warranty and Support: Rest easy with our comprehensive warranty and support package. We stand behind the quality of our product, offering robust warranty coverage and a dedicated support team to address any inquiries.

- User-Adjustable Settings: Empower operators with the ability to fine-tune settings based on specific operational needs. From pressure adjustments to cycle durations, the user-adjustable settings provide a high level of customization.

- Seamless Integration with Existing Systems: Our loading and unloading compressor is designed to easily integrate your existing systems. This Compressor seamlessly integrates with various industrial configurations.

- Multi-Language Interface: Cater to a diverse workforce with a multi-language interface. The user-friendly controls can be customized to display information in different languages.

- Real-Time Performance Analytics: Gain deep insights into your Compressor’s performance with real-time analytics. Track key performance indicators, energy consumption patterns, and other critical metrics through comprehensive data visualization.

Main Structure: Loading and unloading Compressor

- The Loading and Unloading Compressor series is designed to efficiently handle liquefied gases such as LPG, C4, propylene, and liquid ammonia.

- With models like ZW, VW, and ZG, each tailored to specific applications, the compressors boast compact dimensions (1000×710×865 mm to 2400×1700×1550 mm) and motor powers ranging from 4 kW to 132 kW.

- The loading and unloading capacities vary accordingly, ensuring precise and adaptable performance under different conditions.

- Whether it’s the diverse applications of LPG and C4 or the specialized needs of propylene and liquid ammonia, these compressors offer a reliable and efficient solution.

Applications: Loading and unloading compressor

- Marine Industry: Assist in marine operations by providing compressed air for tasks such as ship maintenance, pneumatic tools on board, and control systems. The Compressor’s robust design makes it suitable for the challenging conditions of marine environments.

- Cement and Concrete Production: Contribute to the efficiency of cement and concrete manufacturing processes by supplying compressed air for tasks like pneumatic conveying, material handling, and concrete mixing. The Compressor’s ability to handle varying loads is advantageous in these dynamic processes.

- Hospital and Healthcare Facilities: Support various medical applications in hospitals and healthcare facilities, including operating pneumatic medical devices, laboratory equipment, and HVAC systems. The Compressor’s reliability is crucial in maintaining critical healthcare infrastructure.

- Entertainment Industry: Enhance stage productions, concerts, and events with our Compressor, which can power pneumatic systems for stage effects, and sound equipment. The Compressor’s adaptability is valuable in creating dynamic and immersive experiences.

Compressor for LPG / C4 loading and unloading |

||||

| Model | Motor Power

(kW) |

Dimensions

L×W×H(mm) |

Loading and unloading

(t/h) |

|

| 1 | ZW-0.25/10-16 | 4 | 1000×710×865 | ~5.5 |

| 2 | ZW-0.4/10-16 | 5.5 | 1000×710×865 | ~9 |

| 3 | ZW-0.5/10-16 | 7.5 | 1000×710×865 | ~11 |

| 4 | ZW-0.6/10-16 | 7.5 | 1000×710×865 | ~13 |

| 5 | ZW-0.8/10-16 | 11 | 1000×710×865 | ~17.5 |

| 6 | ZW-1.1/10-16 | 15 | 1000×710×865 | ~24 |

| 7 | ZW-1.35/10-16 | 18.5 | 1000×710×865 | ~30 |

| 8 | ZW-1.6/10-16 | 22 | 1400×900×1180 | ~35 |

| 9 | ZW-2.0/10-16 | 30 | 1400×900×1180 | ~45 |

| 10 | ZW-2.5/10-16 | 37 | 1400×900×1180 | ~55 |

| 11 | ZW-3.0/10-16 | 45 | 1400×900×1180 | ~65 |

| 12 | ZW-4.0/10-16 | 55 | 1400×900×1180 | ~85 |

| 13 | VW-5.0/10-16 | 75 | 2000×1700×1400 | ~110 |

| 14 | VW-6.0/10-16 | 90 | 2000×1700×1400 | ~130 |

| 15 | VW-8.0/10-16 | 110 | 2000×1700×1400 | ~174 |

| 16 | ZG-0.75/10-15 | 11 | 1450×800×1300 | ~16.3 |

| 17 | 2DG-1.5/10-16 | 22 | 1860×1680×930 | ~32.6 |

The unloading volume is determined by considering specific conditions such as an inlet pressure of 1.0 MPa, exhaust pressure of 1.6 MPa, inlet temperature of 40°C, and a liquid density of 582.5 kg/m³ for the liquefied gas. It’s important to note that any variations in working conditions will result in corresponding changes in the unloading volume.

Propylene loading and unloading compressor |

||||

| Model | Motor Power

(kW) |

Dimensions

L×W×H(mm) |

Loading and unloading

(t/h) |

|

| 1 | ZW-0.6/16-24 | 11 | 1000×680×870 | ~15 |

| 2 | ZW-0.8/16-24 | 15 | 1000×680×870 | ~20 |

| 3 | ZW-1.0/16-24 | 18.5 | 1000×680×870 | ~25 |

| 4 | ZW-1.5/16-24 | 30 | 1400×900×1180 | ~36 |

| 5 | ZW-2.0/16-24 | 37 | 1400×900×1180 | ~50 |

| 6 | ZW-2.5/16-24 | 45 | 1400×900×1180 | ~60 |

| 7 | ZW-3.0/16-24 | 55 | 1600×1100×1250 | ~74 |

| 8 | ZW-4.0/16-24 | 75 | 1600×1100×1250 | ~98 |

| 9 | VW-6.0/16-24 | 132 | 2400×1700×1550 | ~147 |

| Liquid ammonia loading and unloading compressors | ||||

| Model | Motor Power

(kW) |

Dimensions

L×W×H(mm) |

Loading and unloading

(t/h) |

|

| 1 | ZW-0.6/16-24 | 15 | 1100×700×900 | ~17.5 |

| 2 | ZW-0.8/16-24 | 18.5 | 1100×700×900 | ~23 |

| 3 | ZW-1.0/16-24 | 22 | 1000×680×870 | ~29 |

| 4 | ZW-1.5/16-24 | 30 | 1400×900×1180 | ~43 |

| 5 | ZW-2.0/16-24 | 37 | 1400×900×1180 | ~58 |

| 6 | ZW-2.5/16-24 | 45 | 1400×900×1180 | ~73 |

| temperature(°C) | atmospheric pressure | temperature(℃) | atmospheric pressure |

| 20 | 8.4585 | 30 | 11.512 |

| 22 | 9.0125 | 32 | 12.212 |

| 24 | 9.5940 | 34 | 12.943 |

| 26 | 10.2040 | 36 | 13.708 |

| 28 | 10.8430 |