Piston type Air Compressor: Cost-Effective Power for Everyday Tasks

Take Charge of Your Projects with Piston Air Compressors’ Dependable Performance

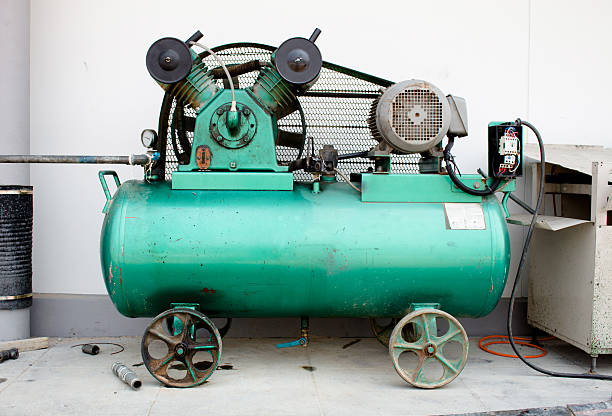

The humble piston type air compressor is a workhorse that is readily overlooked. These adaptable machines provide a compressed air blast to tackle a variety of jobs, from powering pneumatic tools in your garage to fuelling industrial applications. This thorough guide dives into the world of piston air compressors, examining their inner workings, advantages, uses, and important considerations to make sure you choose the right one for your requirements.

How Piston Air Compressors Operate: A Demystification of the Powerhouse

The unsung heroes of workshops and industrial environments, piston air compressors provide compressed air to power a range of operations. However, how precisely does this relatively straightforward device produce such a strong air blast? Now let’s explore the intriguing workings of a piston air compressor:

The Machine’s Core:

Envision a tiny engine consisting of a single piston that oscillates within a cylinder. This is the fundamental idea at work. The procedure proceeds in a cycle with rhythm:

- Intake Stroke:

During the intake stroke, the piston falls and a vacuum is created inside the cylinder. When an inlet valve opens, ambient air might enter quickly.

- Compression Stroke:

As the piston rises, the inlet valve closes and the air inside the cylinder is trapped. The trapped air is squeezed as the piston continues to travel, which raises the pressure.

- Discharge Stroke:

When compressed air exerts enough force to push beyond a discharge valve’s resistance, the valve opens. As a result, the cylinder’s high-pressure air can now exit and enter a storage tank.

- Repetition:

There are constant cycles like this one. More air is taken in, compressed, and released with each iteration, progressively increasing the pressure inside the storage tank.

Oil or Not at All? Comprehending Lubrication

There are two primary lubrication categories for piston air compressors:

- Oil-Lubricated:

The cylinder wear and friction are minimized in these workhorses by using oil. Longer lifespans and higher power outputs result from this, which makes them perfect for demanding applications. However, for jobs like painting or food processing that require clean air, oil pollution may be a problem.

- Oil-Free:

These completely remove oil, offering pure, pollutant-free compressed air ideal in circumstances where oil residue is not wanted. Compared to their oil-lubricated cousins, they may require more regular maintenance and have slightly lower power outputs, but they operate cleanly.

Knowing how a piston air compressor operates can help you select the best one for your requirements. Keep checking back as we examine several varieties, important factors, and the wide range of uses for these adaptable devices!

The Power of Choice: An Examination of Various Piston Air Compressor Types

There are numerous solutions available in the piston air compressor market to meet different purposes.

- Single-Stage Compressors:

These workhorses are effective for household use and basic activities because they only require one compression stage to deliver compressed air.

- Two-Stage Compressors:

These compressors meet the demands of professional applications that call for stronger air blasts by using two compression stages to reach higher pressure outputs.

- Portable Compressors:

Roadside repairs, building sites, and other mobile scenarios can benefit from the portable compressors’ lightweight and compact design, which offers compressed air solutions that are always ready to go.

- Electric Compressors:

Suitable for residential garages and workshops, these electricity-powered compressors operate quietly and cleanly.

- Gas Powered Compressors:

Compressors that run on gas or diesel offer the portability and power required for jobs that require work in distant areas or without easy access to electricity.

Beyond the Specifications: Important Considerations for Selecting the Best Piston Air Compressor

There’s more to choosing the best piston type air compressor than just comparing specs. While tank capacity and horsepower are significant qualities, there are other crucial factors to take into account to make sure you get the right machine for the job. Here are some things to remember:

- Airflow Capacity (CFM):

This represents the amount of air provided per minute and is measured in cubic feet per minute (CFM). Avoid being taken unawares! Select a compressor whose CFM rating is higher than what your pneumatic tools demand. Choose a compressor that easily exceeds the CFM requirements of the tools you intend to utilize after researching their requirements.

- Air Pressure (PSI):

The force of compressed air is represented by the air pressure, which is expressed in pounds per square inch (PSI). It’s critical to match the PSI rating of the compressor to the pressure requirements of your tools. While more PSI than is advised for a tool might cause harm, less PSI can result in slow performance or unfinished jobs.

- Duty Cycle:

This specification describes the compressor’s recommended running time for rest intervals. It’s critical to choose a duty cycle that corresponds with your usage behaviour. For instance, a greater duty cycle rating is required if you want to use the compressor continuously for long periods with little interruptions. Overheating and early compressor failure might result from the duty cycle and utilization being out of balance.

- Tank Capacity:

The compressed air is stored in the air receiver tank. When performing operations that require constant pressure, a larger tank offers a more sustained air supply. A smaller tank can be adequate if you intend to use tools with high air consumption in short bursts. However, a larger tank guarantees that you won’t have pressure reductions between compressor cycles for applications requiring regular air delivery.

Above and Beyond the Stats:

Even though these fundamental requirements are important, take into account other factors:

- Noise Level:

When using a device at home, noise emission can be a problem. If you want a quieter compressor, look for ones with lower decibel ratings.

- Upkeep Needs:

In general, oil-lubricated compressors need more regular maintenance than their oil-free counterparts. Before making a decision, assess your comfort level with maintenance duties.

You’ll be well-equipped to select a piston type air compressor that precisely suits your needs and provides peak performance for many years to come if you are aware of these important factors.

Unleashing Potential: The Diverse Applications of Piston Air Compressors

The workhorses of a surprisingly broad range of applications are piston air compressors. Their capacity to supply compressed air converts into energy for a range of applications in multiple sectors. Here are a few ways piston type air compressor can reach their full potential:

Piston air compressors are indispensable instruments in any vehicle repair shop, used for everything from the routine duty of inflating tires to powering impact wrenches for lug nut removal, spray guns for painting, and sanders for bodywork prep.

- Building:

The power of compressed air is crucial to the building sector. Pneumatic instruments such as concrete breakers, staplers, and nail guns rely on piston air compressors for their effective functioning. Compressors can also be employed in building projects for cleaning and dust removal operations.

- Woodworking:

Compressed air is used for a variety of purposes by woodworkers of all skill levels. Piston air compressors are versatile tools that can be used for sanding furniture, drilling precise holes, driving nails with nail guns, and spray painting.

- Home Improvement:

You don’t have to exclude the do-it-yourself enthusiast. A variety of home renovation tasks can be completed with piston air compressors. These devices come in handy around the house for everything from pumping air into pool floats and bicycle tires to running staple guns for upholstery or paint sprayers for revitalizing furniture.

Beyond the Explicit:

There are many more uses for these. Uses for piston air compressors include:

- Manufacturing:

For running equipment that needs compressed air, such as assembly line tools.

- Food Processing:

For bottling and packing applications utilizing pneumatic equipment.

- Dental labs:

These are where drills and other instruments needed to make dental prostheses are powered.

- Sandblasting:

A high-pressure stream of abrasive material driven by compressed air is used to remove paint, corrosion, and other surface impurities.

The Benefits of Piston Type Air Compressors: The Power of Simplicity

Piston air compressors are distinguished in the industry by their ease of use, dependability, and adaptability. These workhorses are quite beneficial for all kinds of activities and budgets. For the following reasons, piston type air compressors could be the ideal choice for you:

- Economical:

Piston types are generally less expensive than rotary screw compressors, making them an economical choice for both experts and do-it-yourselves. They are perfect for home workshops and applications with mild air demands because of their cheaper starting cost.

- Simple Maintenance:

Because piston compressors have a clear design, maintenance procedures are easier to follow. Because routine oil changes and filter replacements are frequently the only maintenance needed, even non-mechanics can easily operate them.

- Vast Variety of Options:

They are available in a range of sizes and configurations, from small, portable machines to strong, stationary equipment. This guarantees you don’t pay for more capacity than you’ll ever use by letting you select the ideal size and power output for your unique requirements.

- Dependable Performance:

The dependability of piston compressors has been demonstrated in the past. Because of their straightforward construction, which reduces the number of parts that can go wrong, they are trustworthy workhorses for regular duties.

Conclusion:

Offering complete, one-stop solutions, LEIYAO Compressor guarantees great product quality and first-rate service to our global clients. The organization possesses sophisticated technical testing facilities and techniques, drawing from its vast experience in both design and manufacture.