Piston Compressor Manufacturers: What to Look for in 2024

The Ultimate Guide to Piston Compressor Manufacturers:

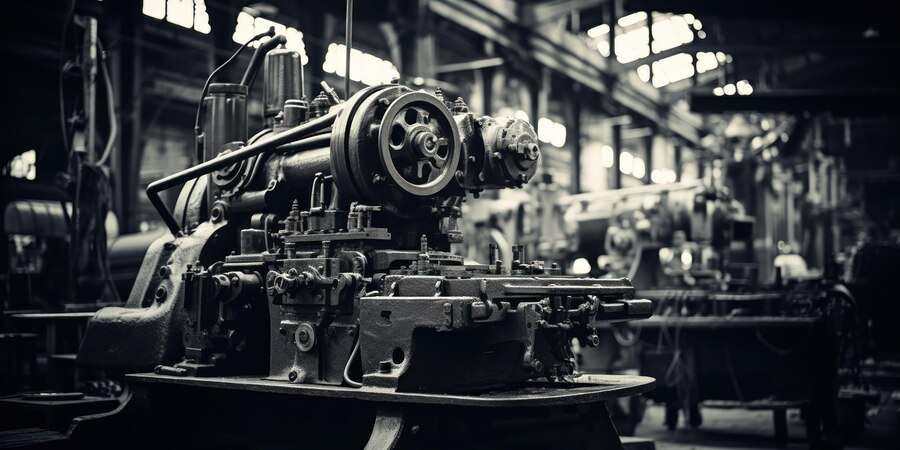

Piston compressors are one of the greatest assets that you can have in the world of industrial machinery. Whether you are in the manufacturing industry, construction industry, or any industry that requires the use of compressed air, then you need to understand the piston compressor manufacturers market.

Experiencing the Incredible Piston Compressor

To understand the mechanism of piston compressor operation, there is a basic principle that needs to be described first of all. Think about a cylinder that has been tightly closed at one end while the other end has a piston that should move to and fro. When the piston rises, the head creates a vacuum, thereby sucking air in the chamber. During the top dead center, the piston pulls the air into the cylinder but during the bottom dead center, the air gets compressed and a powerful pressurized air rushes through the valve. This air can be used in so many ways ranging from driving nails and inflating tyres to driving very complex gadgets.

Key Types of Piston Compressors:

Single-Stage Piston Compressors: These are single-cylinder type compressors and are developed to deliver the air at comparatively lower pressure.

Multi-Stage Piston Compressors: With multiple cylinders, these compressors can develop higher pressures, and so are more appropriate for use in the applications.

Oil-Lubricated Piston Compressors: These utilize oil to minimize the friction of moving parts hence helping in increasing the compressor’s useful life.

Oil-Free Piston Compressors: Ideal for companies that must minimize oil presence in their production such as the food processing and manufacture of drugs.

Why Piston Compressor is Preferred?

Piston compressors offer several benefits:

• High Efficiency: It can deliver high pressure and therefore the pressure is good for high-use purposes.

• Versatility: Its variations are mainly determined by size as well as the layout of the exterior frame.

• Durability: Piston type can last many years hence the need to make sure you carry out regular maintenance on these compressors.

Key Considerations When Choosing a Piston Compressor Manufacturer

Reputation and Experience: The buyer should look for manufacturers that have a track record of efficiency in their work. This is a factor in that most established businesses will usually possess the skills as well as experience needed to generate superior products.

Product Range: It is important to select a manufacturer that has a variety of piston compressors which may include single-stage, multi-stage, oil-lubricated, and oil-free.

Technical Support and Maintenance: It should be noted that reliable manufacturers are to provide broad support as well as maintenance services. This way, the possibility of something going wrong is kept to the minimum and such difficulties can be solved immediately.

Customization Options: Thus the Type of Problem that you are solving may call for specific solutions. First, they have to make sure that the manufacturer is capable of meeting these capacities.

Leading Piston Compressor Manufacturers is LEiYAO

LEiYAO ranks among the leaders of the world piston compressor market, with the company capable of producing over one million units a year. We operate in more than 20 countries and regions as far as international presence and service are concerned. Working for us is a team of 500 qualified employees who contribute toward innovation and operational efficiency in our network.

- With a physical presence in three countries, we operate two high-tech Integrated Manufacturing Centers, four sales-only offices as well as a worldwide Business Services Center. The backbone of our capabilities is a well-developed platform for research and development; The Company has more than 10 labs for research and development.

- We currently have close to 600 active patents in our possession proving our constant commitment to ensuring innovative technology and Intellectual property. Quality and innovation are LEiYAO’s distinctive strengths allowing us to be the company of the first choice for customers who require efficient piston compressors and other Industrial products.

How to Evaluate Piston Compressor Manufacturers?

When evaluating potential piston compressor manufacturers, consider the following:

• Quality Certifications: Make sure that the manufacturer’s products suit the standard standards of the industry and have been certified.

• Customer Reviews: Search for comments made by other customers on the website to determine the reliability of the manufacturer as well as the performance of the compressors as offered.

• Warranty and Guarantees: It can also put consumer’s minds at ease with the security that comes from a good warranty.

Service Guarantee by LEiYAO

For LEiYAO, what we convey is not just piston compressors with excellent quality, this is where we start. Our strength is in providing technical backup and support to help our customers find solutions as well as utilization of our products in the best way possible. Our service guarantee encompasses three crucial areas: pre-sales support, including order taking and other services related to the sale as well as the post-sale complementary services.

- Strategically tasked with technical support to enable speedy handling of our client’s needs after sale, we have what it takes. We are involved from the drawing board process right to the last step of training the employees on how to operate the system. It also provides after-sales service for our clientele and because of this commitment to excellence added value is given to the buyer throughout the cycle of using the equipment.

- No matter whether the systems integration is on your schedule or the systems you have in place require support, LEiYAO aims to ensure your experience is improved with quick and professional support. We are committed to achieving high standards of service to ensure that you are catered for in the best way possible.

The Role of Piston Compressors in Different Industries

Manufacturing: In manufacturing, the piston type is used for powering air tools and equipment such as pneumatic compressors. It enables them to support in enhancing efficiency and productivity on the shop floor.

Construction: At construction sites piston compressors find application in several areas like operation of tools as well as equipment.

Oil and Gas: Piston compressors are widely used in the oil and gas industry mainly because they are used in the transportation of gases as well as the regulation of pressures in pipelines.

Maintenance Tips for Piston Compressors

Make sure to follow these points so that your piston compressor can serve the longest time possible. Here are some tips:

• Lubrication: It is good to lubricate the compressor to make the friction and wear low.

• Filter Replacements: Clean the filters from time to time to ensure that the air conditioners work as supposed to.

• Cleanliness: Some of the important factors regarding this device include: The compressor and its parts should be cleaned to reduce or eliminate contamination.

Conclusion:

Choosing the right piston compressor manufacturers is crucial for ensuring that your industrial processes run smoothly. By considering factors such as reputation, product range, and support services, you can make an informed decision that best suits your needs. For more information on piston compressors and to explore various options, visit LEiYAO, where you can find detailed insights and product offerings tailored to your requirements.