Oilfield Compressor Guide

Introduction

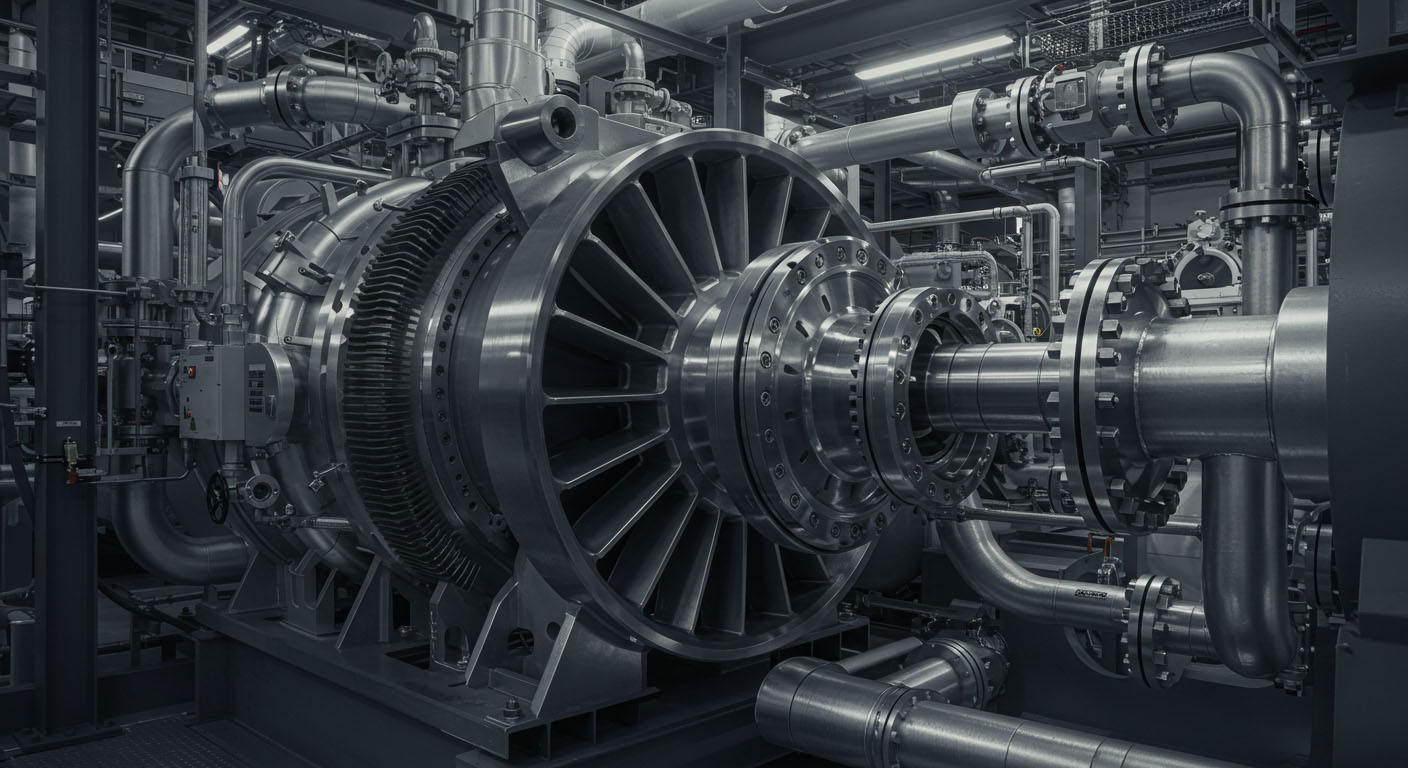

In the vast world of oilfield operations, where every component plays a crucial role, oilfield compressor stand out as indispensable workhorses. They are the unsung heroes that ensure the smooth flow of oil and gas, maintaining the delicate balance of pressure and flow rates deep beneath the Earth’s surface. This comprehensive guide will delve into the world of oilfield compressors, demystifying their functions, types, key components, applications, and much more. So, let’s embark on this journey to understand the heart of oilfield operations.

Types of Oilfield Compressors

- Reciprocating Compressors

Reciprocating compressors, as the name suggests, operate through a piston-like motion. They work by drawing in gas and then compressing it in a cyclic manner. These compressors find applications in various oilfield operations, from gas lift for well stimulation to enhanced oil recovery.

- Rotary Screw Compressors

Rotary screw compressors utilize two helical rotors to compress gas. This design ensures continuous airflow and is highly efficient, making them suitable for oilfield applications where a constant supply of compressed gas is essential.

- Centrifugal Compressors

Centrifugal compressors use a high-speed impeller to accelerate gas and then convert the kinetic energy into potential energy. They excel in handling large volumes of gas at high pressures, making them invaluable in oilfield operations.

Key Components of Oilfield Compressors

A. Compressor Units

Compressor units are the heart of any compressor system. They consist of the compressor itself, a motor or engine to drive it, and various ancillary components to ensure its smooth operation. Understanding their function and maintenance is crucial for reliable performance.

B. Cooling Systems

Efficient cooling systems are vital for preventing overheating and ensuring the longevity of compressors. This section will highlight the importance of cooling systems and the different types available.

C. Control and Safety Systems

In oilfield operations, safety is paramount. Control and safety systems play a pivotal role in monitoring and safeguarding compressor operations. Learn how these systems contribute to safe and reliable operation.

Applications of Oilfield Compressors

A. Gas Compression

- Gas Lift for Well Stimulation

Discover how oilfield compressors are used for gas lift operations, a technique that enhances oil and gas recovery from wells.

- Enhanced Oil Recovery

Explore the role of compressors in enhanced oil recovery methods, where they play a critical role in maintaining reservoir pressure.

B. Vapor Recovery Units (VRUs)

Learn how VRUs, equipped with compressors, help reduce emissions in oilfields, contributing to environmental sustainability.

C. Wellhead Compression

Maintaining consistent wellhead pressure is essential for efficient oil and gas production. This section explores how compressors achieve this vital task.

Factors to Consider When Selecting an Oilfield Compressor

A. Capacity and Pressure Requirements

Understanding the specific needs of your oilfield operation, in terms of capacity and pressure, is crucial for selecting the right compressor.

B. Environmental Considerations

In today’s environmentally conscious world, choosing compressors that align with sustainable practices is essential. Learn about eco-friendly options.

C. Reliability and Maintenance Needs

Reliability is key in oilfield operations. Discover how selecting a reliable compressor can minimize downtime and maintenance costs.

Leading Manufacturers and Models of Oilfield Compressors

A. Prominent Compressor Manufacturers

Get acquainted with the leading manufacturers in the industry, known for their high-quality compressor solutions.

B. Highlighted Models and Their Features

Explore specific compressor models renowned for their performance, efficiency, and durability.

Case Studies

A. Real-World Applications of Oilfield Compressors

Delve into real-world examples of how oilfield compressors have been successfully employed in various applications.

B. Success Stories and Performance Enhancements

Learn about success stories where compressors have significantly improved oilfield operations and performance.

Future Trends in Oilfield Compressors

A. Innovations in Compressor Technology

Stay ahead of the curve by exploring the latest innovations in compressor technology that are shaping the future of oilfield operations.

B. Sustainable Practices in Oilfield Operations

Discover how sustainability is becoming increasingly important in the oil and gas industry and the role of compressors in achieving environmentally friendly practices.

C. Integration with Digital Solutions for Monitoring and Control

Learn how digital solutions are revolutionizing oilfield compressor monitoring and control for enhanced efficiency and safety.

Conclusion

As we conclude this journey through the world of oilfield compressors, we hope you now have a comprehensive understanding of their significance and versatility. Oilfield compressors are not just machines; they are the driving force behind the ever-evolving oil and gas industry. We encourage you to explore compressor solutions that can elevate your oilfield operations to new heights. With constant innovation and a commitment to sustainability, the role of compressors in the industry’s future is brighter than ever.