Welcome to the forefront of compressed air technology with our Oil-Free Screw Air Compressor – a pioneering solution redefining efficiency, reliability, and environmental responsibility standards. Designed to meet the exacting demands of modern industries, this compressor represents a leap forward in air compression. It also offers many features, making it an indispensable asset across diverse applications.

From cutting-edge screw technology to smart control systems, our Oil-Free Screw Air Compressor stands as a testament to innovation, delivering pristine, oil-free compressed air with a commitment to sustainability.

Key Features & Characteristics:

The key features and characteristics are:

- Cooling System Efficiency: The compressor incorporates an advanced cooling system to maintain optimal operating temperatures. This enhances overall efficiency and extends the lifespan of critical components.

- Noise Reduction Technology: Engineered with noise reduction technology, this compressor ensures a quieter working environment. It is perfect for installations where minimizing noise pollution is a priority.

- Digital Connectivity: Embrace Industry 4.0 with the compressor’s digital connectivity features. Real-time monitoring, remote control, and predictive maintenance capabilities enhance operational transparency and facilitate proactive maintenance planning.

- Adaptive Control Algorithms: The compressor employs adaptive control algorithms, dynamically adjusting to fluctuations in demand. This responsive control mechanism enhances performance efficiency and maintains a steady supply of compressed air, even during peak demand periods.

- Environmental Compliance: The Oil-Free Screw Air Compressor is committed to sustainability and meets or exceeds environmental regulations and standards. Its design minimizes carbon footprint, making it eco-friendly for conscientious businesses.

- Integrated Control System: The built-in control system offers user-friendly interfaces for easy monitoring and operation. It allows precise control of the compressor’s performance, ensuring optimal efficiency and adaptability to varying workload demands.

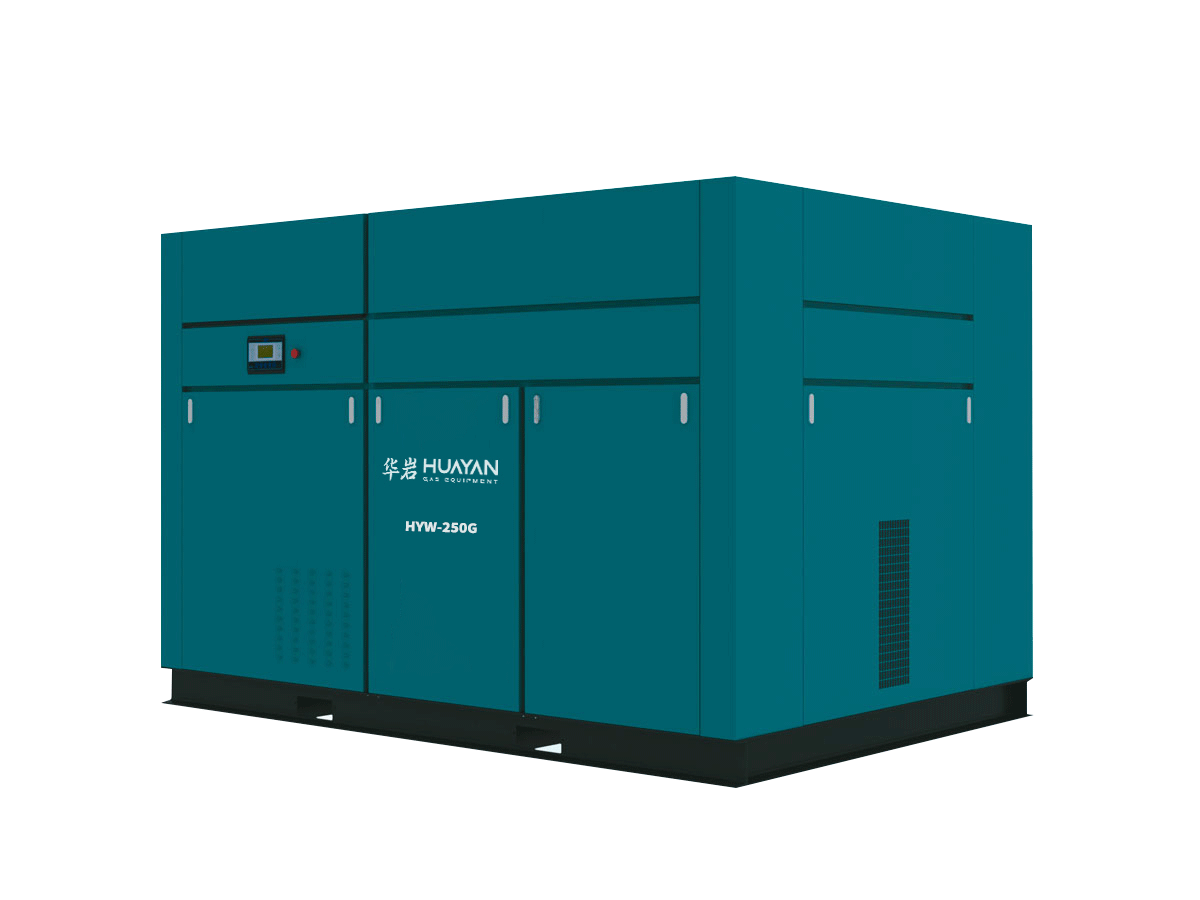

- Compact Design: Space is often a valuable commodity in industrial settings. Our Oil-Free Screw Air Compressor is designed with a compact footprint, making it suitable for installations where space is at a premium.

Applications

Elevate your operations with a compressor that not only meets but exceeds the expectations of today’s dynamic industrial landscape.

- Pharmaceutical Manufacturing: Essential for pharmaceutical manufacturing processes that demand a sterile environment, our compressor ensures the integrity of critical medications and medical supplies.

- Biotechnology Laboratories: In biotech labs where precision is paramount, this compressor provides contaminant-free air for experiments, ensuring accurate and reliable results.

- Clean Room Environments: Suitable for clean room applications in industries such as semiconductor manufacturing, where maintaining an ultra-clean environment is critical for product quality.

- Research and Development Facilities: Laboratories and R&D facilities benefit from the compressor’s oil-free operation, supporting diverse experiments and studies without the risk of air contamination.

- Wastewater Treatment Plants: Plays a crucial role in aeration processes within wastewater treatment plants, delivering clean and oil-free air for efficient water purification.

- Plastic and Rubber Manufacturing: Addresses the specific requirements of plastic and rubber manufacturing processes, ensuring that the compressed air does not compromise the quality of the end product.

Investing in our Oil-Free Screw Air Compressor provides a comprehensive solution for various industries, demonstrating a commitment to efficiency, reliability, and environmental responsibility.