Maximize Your Productivity with a Reliable Piston Air Compressor System

Discover LEiYAO Compressors: Industrial Compressors & Motor Manufacturers

At LEiYAO, we honor ourselves in being one of the leading companies in industrial compressors and motors. We have a monthly production capability of over 100,000 units, and within 20 countries and regions, we supply solutions that meet quite a number of requirements.

What is a Piston Air Compressor?

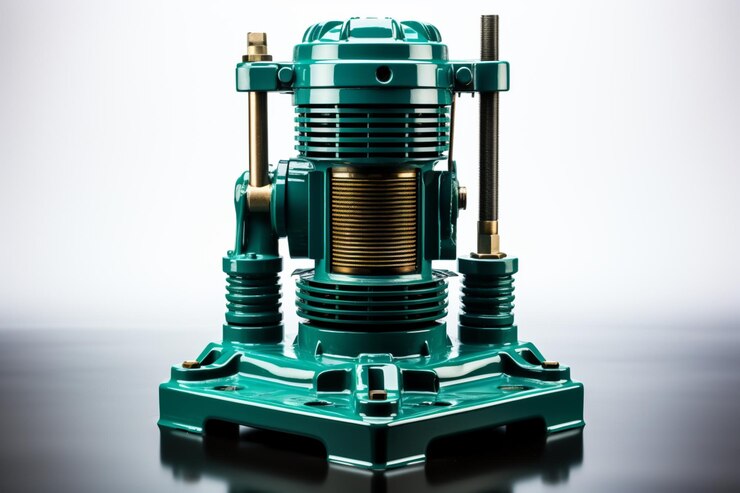

That is distinguished by the fact that is can be defined as a piston air compressor is a mechanical device that employs a piston to compress air. Such a method produces compressed air that is then stored in an air tank for use later on. Screw air compressors also come under a category of reciprocating air compressors piston air to be more precise piston compressors are one of the most reliable and used air compressor types.

How Does it Work?

The working of a piston air compressor system is relatively simple. During the down stroke, a piston pushes the gases down and, as a result, a vacuum is formed due to the collapse of the cylinder gases which then act to draw the air into the crankcase through an intake valve. The piston then moves back up and thereby compresses the air so as to increase pressure in the chamber. This compressed air is then forced out through a discharge valve into an air tank as indicated in the next figure.

Advantages of Piston Air Compressor System

The popularity of piston air compressor system can be attributed to their numerous advantages:

- Versatility

These systems are also suitable for commercial and industrial use and flow control in residential systems. From the piston compressors for home use to those that are stationary for a manufacturing line, there exists a piston compressor to suit your needs.

- Cost-Effectiveness

There are various types of air compressors, but piston-type air compressors are generally cheaper as compared to other types. They are less expensive to set up than a proper metal building, and as such appeal to small business people and DIY people.

- Reliability

Piston compressed air machines are very well-designed and continue to provide service for extended periods of time. As long as they are properly maintained they will give you years of service.

- Easy Maintenance

Maintenance is simple, including the changing of oil and filters on a regular basis with little need for a mechanic’s expertise.

Major Parts of a Piston Air Compressor

When you want to know how to maintain a piston air compressor, it’s important to first understand some of the primary constituencies of the unit.

- Air Tank

The received air is stored here in a compacted form and makes a middle-man between the air compressor and the pneumatic tools. It assists in the regulation of pressure during the USE of the affective AIR PRESSURE.

- Air Filter

An air filter prevents contaminants from entering the intake system of a vehicle, thus only clean air entering the system is admitted. This is important in order to avoid a case of damage to the compressor and to maximize its life span.

- Air Dryer

This device gets rid of water from compressed air through processes of cooling and adsorption. This is very important to avoid cases where your tools and machinery rust and corrode.

- Pressure Regulator

A pressure regulator is a device that helps in regulating the pressure of the air according to a user-specified requirement.

- Air Hose

Air hose is used to link your compressor to your pneumatic tools, it transports the compressed air to anywhere it might be required.

Uses of Piston Air Compressors

Piston Air Compressor system find applications across various industries:

- Automotive

Piston-type air compressors are used in the automobile industry where pneumatically operated tools like the impact wrench, paint sprayer, and tire inflater. They are highly useful for use in repair shops as well as manufacturing industries.

- Construction

Many construction areas use piston air compressors for equipment such as nail guns and jackhammers. These types are portable, convenient objects that can be used on tough tasks and assignments.

- Manufacturing

Gardner Denver compressors in manufacturing use air for various applications in assembly lines and material transportation systems.

- Healthcare

Offers of oil-free piston compressors are most critical in the health sectors as these provide clean and compressed air to medical facilities.

Selecting the Right Piston Air Compressor

When selecting a piston air compressor system, consider the following factors:

- Application Needs

By figuring out the exact uses of the compressor, you will have figured out what is most suitable. This will tell you whether you need a mobile or fixed system as well as the pressure and capacity needed.

- Size and Portability

When considering moving the compressor often, you should consider the portable piston compressor. If for a fixed location, a stationary piston compressor might be desired most as compared to other kinds of piston compressors.

- Noise Levels

Narrow down the loudness of the compressor, should you be operating it in residential areas or in enclosed spaces. Make an effort to find models that have smaller decibel values.

- Maintenance Requirements

Some of the models need frequent attention more than others. If looking for a low-maintenance type, there are compressor models that do not use oil.

Our Global Reach

Our operations are wide-range and they Employ 500 staff, all of whom work together to achieve the mission statement. To coordinate our operations, we have two manufacturing plants, four sales offices and a Global Business Support Centre in three countries. Such a strong foundation allows us to act quickly in satisfying customers’ requirements and fulfilling market expectations.

- Innovation at Our Core

A compel package to the group is innovation which is the pulse of LEiYAO. We have over ten research and development laboratories in order to continuously improve products and services. We underline a dedication to progress in technological fields and leadership in industries by referring to 594 valid patents. This commitment to higher technology keeps our industrial compressors and motors line at the highest level of efficiency and durability.

- Our Vision and Mission

In line with our vision of Innovation for Industry advancement and integrity as a world-class company’’ we aim for maximum customer satisfaction. We are focused on increasing the happiness of employees all the time, as satisfied employees are the primary makers of outstanding results.

- Commitment to Quality

As for LEiYAO, we are full of commitment to our development ideology of Providing Exceptional Technology, Procuring High-Quality Equipment, and Delivering Outstanding Service. We supply industrial compressors and motors and make sure that they are standardized in the market to provide efficient results.

Our Core Values

Our values reflect our commitment to excellence:

• Innovation and Excellence

• People-Centric Focus

• Integrity as a Priority

These principles govern our ethos and way of working allowing us to foster long-term relations with customers & partners.

Join Us at Our Exhibitions

We encourage you to meet with us at future exhibitions where we will present new products. The authors and their team are ready to collaborate, to exchange experience, knowledge, and information with other professionals in the industry. Please check our exhibition listing to see how our products containing innovative features work as intended!

Conclusion

The Piston Air Compressor system is a vital tool in various industries and applications, offering versatility, reliability, and cost-effectiveness. Whether you’re a DIY enthusiast or a business owner, understanding this powerful system can help you make informed decisions for your air compression needs. For more information on piston air compressors and to explore a wide range of models, visit LEiYAO Compressors.