LEiYAO Ethane Compressor is the Leading the Way in Industrial Gas Compression

The Ultimate Guide to Ethane Compressors:

Ethane compressor is one of the important pieces within the vast catalog of industrial equipment. These powerful machines are helpful in the processing and movement of ethane, an important material in the petrochemical sector. In this article, the reader will find out the most common types of ethane compressor, their use, and their contribution to gaining efficiency and ever-growing environmental impact in gas processing.

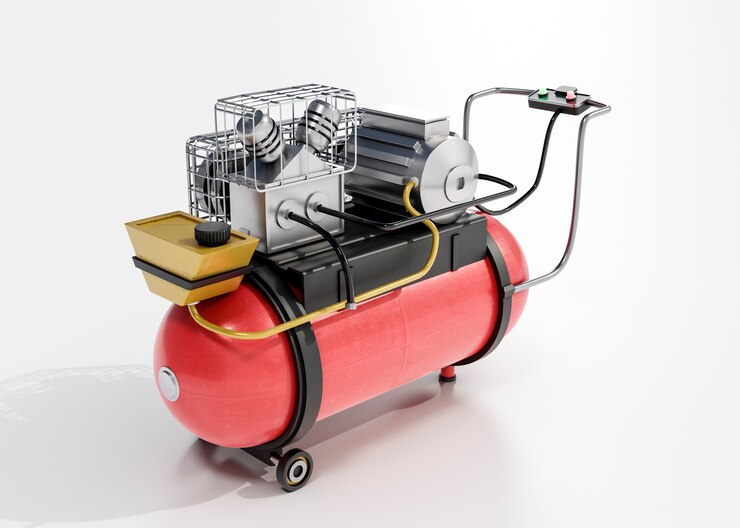

What is an Ethane Compressor?

Basically, an ethane compressor is simply only a specialized kind of gas compressor for the purpose of compressing the ethane gas. The process is important for the transport and storage of ethane to be accomplished efficiently. It is mainly utilized to produce ethylene used in the creation of numerous plastics and other chemical products, with ethane being a component of natural gas.

Why Ethane?

Ethane is chosen for its non-toxic nature as well as its being readily available in natural gas. As the appetite for cleaner power supplies keeps rising, knowledge of the functions of ethane compressors has never been more valuable. These compressors not only aid in the process of ethane recovery and storage but are also instrumental in the ethane fractionation process where ethane is separated from other hydrocarbons.

Types of Ethane Compressors

The ethane compressor is available in many types and sizes and is developed to suit different industrial purposes. Here’s a closer look at the main types:

- Reciprocating Ethane Compressors

Reciprocating compressors apply a piston that is operated through a crankshaft. They are very reliable and when used their effectiveness is experienced hence why they are common in many industries. Suitable for low volumetric flow applications, these compressors are great for applications where high accuracy of compression is needed.

- Centrifugal ethane compressors

Centrifugal compressors work under the principle of kinetic energy which is a force and pressure energy. They are best optimized for high-flow applications and therefore can be recommended for large production organizations in the petrochemical industry. These advantages of batch process reactors and their ability to maintain high efficiency at high capacities make them the favourite of manufacturers.

- Positive Displacement Ethane Compressor

Positive displacement compressors enclose a particular volume of gas and then compress this amount to raise its pressure. This method is fast and can be applied in most processes within the oil and gas industry.

Uses of Ethane Compressors

Ethane compressor are not only tools; they refer to crucial parts that facilitate the functioning of different processes in industries that utilize ethane. Here are some key applications:

- Ethane Recovery

In ethane recovery processes, compressors assist in removing ethane from natural gas. This process is very important to ensure that all raw materials attributed with certain yields are utilized effectively and the entire yield from raw materials is realized.

- Ethane Fractionation

Fractionation as a process entails the isolation of the ethane from other hydrocarbons. This requires the use of ethane compressors to help industries enrich and separate ethane for use in the manufacturing and production of chemicals.

- Ethane Storage

To ensure that the quality of ethane is retained, proper storage is required. Compressors maintain optimum pressure on ethane storage and also minimize escapes and wastage.

- Ethane Transportation

If ethane is to be transported safely and effectively the best tool available is the compression technique. Ethane compressors help to transport ethane through pipelines without leakage, where it is required.

- Impact on Industries

There are few industries such as petrochemical, chemical, and oil and gas industries where ethane compressors are not an essential part. They facilitate the management of work processes, containing costs and promoting increases in efficiency.

Compressor Efficiency: The Key to Success

This article aims to understand ethane compressors and rushed efficiency in compressor operations in specific operations. Factors influencing efficiency include:

• Design and Technology: Compressors used in the advanced industrial world are engineered to give maximum output with minimal consumption of energy.

• Maintenance: Schedules work has to be provided to make sure that compressors are always working in the best possible manner. Failure to maintain your car reduces efficiency which also means you have to spend more money when you have to repair the car.

• Operating Conditions: It has been ascertained that several factors present in the environment of operation of the compressor influence it. Manipulation of these conditions must be done appropriately to result in enhanced performance.

Tips for Enhancing Compressor Efficiency

Regular Maintenance: It is advisable to follow up with scheduled checkups and servicing of compressors to ensure they are in good working condition.

Monitor Performance: Ensure that you employ the right monitoring equipment through which you can track the performance indicators to see where you are lagging behind.

Invest in Upgrades: More emphasis should be placed on the more efficient compressors of the modern world rather than sticking to the aged compressors that have lower efficiency and high breakdown rates.

How to Make the Right Decision?

When it comes to selecting the right compressor for your needs, consider the following factors:

• Application Requirements: Also know the current requirements for the operation of your unit, the amounts of flow and pressure, and other conditions.

• Manufacturer Reputation: Always go for compressors with renowned manufacturers that have a good reputation and offer quality machines.

• Energy Efficiency: When selecting compressors for use in the system, the best are those that use less energy while still providing the best output.

• Support and Maintenance: Availability of support and maintenance services should also play a key factor when choosing the supplier of a compressor.

Key Players in the Ethane Compressor Market is LEiYAO

In light of this, there is one key perspective concerning the ethane compressor market buyers that is equally important, and that is market considerations. Among our company has become one of the most significant players favoring the development of new forms and young people’s ideas regarding quality. Currently, we are a professional compressor manufacturer with high operating efficiency that is suitable for a wide range of industries such as ethane processing. Our compressors are known for:

• Advanced Technology: The designs of LEiYAO utilize new technological concepts and improve work performance and credibility.

• Diverse Range: We provide reciprocating, centrifugal, and screw types of compressors with the guarantee of service delivery for each of them.

• Focus on Sustainability: Through its constituency to decrease emissions and increase energy efficiency, LEiYAO is a leading company offering sustainable compressor solutions.

We are a professional manufacturer in the ethane compressor field and working with us means working with a company that is committed to introducing new technologies and products to the market.

Conclusion

They are more than just machines; they are vital tools that help propel the petrochemical industry forward. Whether you are in the petrochemical, chemical, or oil and gas industries, investing in the right compressor is crucial for success. By keeping an eye on the latest advancements in technology and prioritizing maintenance, you can ensure that your operations run smoothly and efficiently. Embrace the power of these compressors from LEiYAO, and watch your productivity soar!