How to Choose the Right Gas LPG Compressor for Your Needs?

The Ultimate Guide to Gas LPG Compressors About Efficiency, Application:

Today’s world is industrial and rapidly progressing, therefore it requires efficiency and reliability in gas compression systems. Meet the Gas LPG Compressor, an unrivaled force in the field of gas compression and delivery. No matter what industry you work in – ranging from the petroleum industry to food processing or automotive industry-LPG compressor details can be very useful to gain an advantage over the competition.

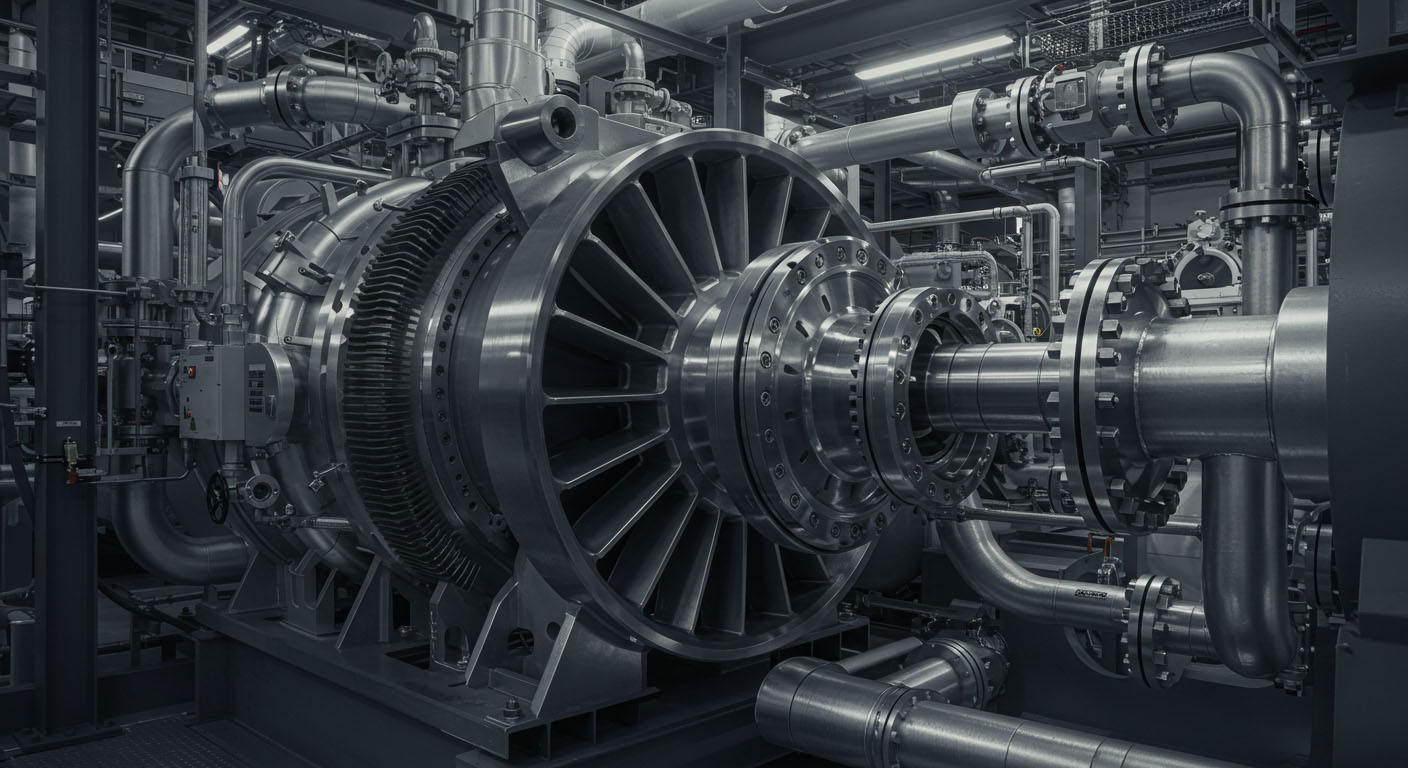

What is a Gas LPG Compressor?

A gas LPG compressor is a reciprocating compressor that seeking when searching for a compressor for use with LPG. Fundamentally, it’s a mechanical item used to increase the pressure of Liquefied Petroleum Gas (LPG) which is most often propane or butane. This causes the pressure of the gas to be compressed making its storage, transportation, and utilization enhanced across the needed uses. There are different types of compressors in use and all are special in their way. Ranging from industrial high-pressure LPG compressors to domestic-type LPG compressor used in a normal home setting, there is a model for each use.

Use of Gas LPG Compressors:

That is why gas LPG compressors enjoy a wide spread in different industries due to their flexibility. Here’s a glimpse into where these machines are making a difference:

- Petroleum Industry:

LPG compressor is used in the petroleum sector to compress the gas for refining as well as for transportation. They are utilized to reduce the volume of natural gas and propane for purposes of storage and transportation to make sure energy is provided to the consumers.

- Chemical Industry:

Since the synthesis of chemicals and operation of the industry requires the use of gasses, the use of gas compression equipment is inevitable for the industry. LPG compressors that are required come into the required pressure costs for these operations.

- Automotive Industry:

It is also used by the automotive industry in compressors wherein it serves as compressed fuel as well as the primary raw material for processing and generation of power. They also are widely used in automotive repair shops and at gas stations where they are stored to be mobile when needed.

- Refrigeration and Heating:

From refrigerators to maintaining heat in your home, you might be surprised to find that these compressors are not far from your reach. They are the driving force behind fridges heaters, and other appliances that require the proper operation of the compressed gas.

- Power Generation:

LPG compressors are another good source of energy especially when in areas that lack electrical power or during a power blackout. Some of them are employed to compress the gas for backup generators and to keep important services going when there is no electricity from the grid.

Choosing the Right LPG Compressor for Your Needs:

Selecting the right LPG compressor involves considering several factors, including:

• Pressure Requirements: Now that you know how the two types of thermoplastic piping systems work, you need to consider whether you require a high-pressure or low-pressure system for your application.

• Volume of Gas: Think of how much gas you are going to require and how much compression it will need to go through. The screw and centrifugal compressor is best applied in large capacities while the reciprocating one is good for small quantities.

• Portability: Succinct the usefulness of a portable compressor to a certain operation and the usefulness of a stationary one. There are mobile compressors as well as fixed or stationary types of compressor equipment depending on the need of the user.

• Maintenance: After comparing the performance of the two types of compressors, one needs to look at the aspects of maintaining the compressor. In general, rotary and screw compressors entail reduced maintenance requirements suitable for constant use.

• Cost: Consider the price of the compressor along with the price of its parts, as well as fees for maintenance and usage. There is also the fact that energy-efficient models may be slightly more expensive but they will help cut costs in the future.

Advances in LPG Gas Compressor Technology

The global market of LPG compressors is full of innovations that contribute to increased performance and improved efficiency. Here are some of the latest innovations:

- Advanced Monitoring Systems:

Present compressors used in the LPG industry are provided with monitors that display pressure, temperature and energy used by the equipment. This data enables operators to fine-tune compressor performance and thereby avoid possible problems at their source.

- Oil-Free Compressors:

To minimize their effects on the environment, there is a trend nowadays for manufacturing oil-fewer compressors that do not require lubrication. This compressor comes in handy when using oil is prohibited such as in the food processing and pharmaceutical industries.

- Compact Designs:

Since companies are extending efforts to make the most of available floor space, portable LPG compressors have continued to be compact. These models have an equal efficiency as the large ones, however, they need a smaller installation area, which is convenient for overcrowded industrial settings.

- Enhanced Durability:

Modern LPG compressors are more durable as the Department of Material Science and Engineering allows the manufacturing of better parts. To minimize the costly effects of corrosion the components and coatings of the compressors used are made of stainless steel and other resistant metals.

Safety Considerations for LPG Compressors:

As we all know LPG compressors are amazing tools to have, however, one must not forget that safety comes first. Here are some key safety considerations:

• Proper Ventilation: Check that the deployment location of the compressor is properly aired in a bid to discourage the accumulation of gas.

• Regular Maintenance: This is why inspections should be carried out periodically so that the technician can determine whether there is anything that requires attention from the owner; or whether the compressor is in good condition and ready to continue providing the required services. Examine the appliances for any possible leakages and any visible signs of wear and tear as well as malfunctioning.

• Training: Make certain that all the operators of LPG compressors have been trained adequately on the use and the maintenance. This may involve having a good appreciation of the safety measures within the car and the possible measures to be taken during an emergency.

Conclusion:

In today’s demanding industrial landscape, the right Gas LPG Compressor can make all the difference. LEiYAO’s range of advanced compressors is engineered to meet your specific needs, whether you’re looking for high-pressure solutions, portable options, or energy-efficient designs. Choosing LEiYAO means investing in quality and performance, backed by cutting-edge technology and a commitment to environmental sustainability. Enhance your operations, reduce costs, and improve energy efficiency with our Gas Compressors. Explore our selection today and discover how our compressors can elevate your business to new heights.