Gast Piston Air Compressor Features: What You Need to Know?

Understanding Reciprocating Compressors

As far as air compression is concerned, there is no better name as famous as Gast. With a high reputation for stability and high performance, the Gast piston air compressor is widely applied in various fields including medical and industrial fields. In this guide, we’ll focus on the basics of Gast piston air compressors starting with the basic principles of how they work to the common applications that use them as well as the benefits of using them.

What is a Piston Air Compressor?

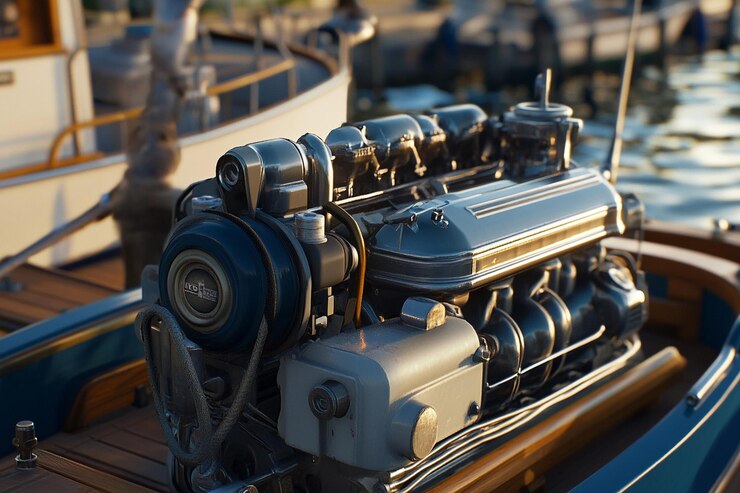

A piston air compressor works where air is compressed as a result of the piston movement inside an engine cylinder. It consists of an intake valve that allows air to be taken inside a cylinder, and the pressure of which is then built up. This compressed air is then used in the following applications; hence it is an essential tool in production.

Key Features of Gast Piston Air Compressors

Efficiency

Gast piston air compressor is known to be very efficient. They are intended to achieve maximum air delivery together with pressure in relation to power consumption. It also leads to reduced costs as far as electricity is concerned not to mention the general reduction of the firm’s impact on the natural environment.

Durability

These have been made from high-quality materials thus they withstand the pressures of use in their operations. From the field in an industrial area with the noise of many machines in operation to a calm dental clinic, gastric compressors remain up to the task in terms of performance.

Low Noise Levels

Another common attribute that users identified about many Gast piston air compressors is that they are quiet when functioning. It would be more applicable in these environments such as dental offices and hospitals in regard to noise as an issue.

Compact Design

Gast compressors are designed to concentrate on the aspect of space. The various models are flexible and small in size which increases their usability when placed in multiple scenarios.

User-Friendly Interface

Some of the Gast piston air compressor models are designed with basic features allowing them to be easily controlled. These compressors cannot even be mistaken for sophisticated equipment since they can be operated by anyone including people with a bit of technical knowledge.

Innovation Driving Industry Progress; Integrity Shaping a Global Brand

Corporate Vision

At LEiYAO, it is our vision to break new ground of innovations in our industry and consolidate our positions based on sincere professionalism that is embraced internationally.

Consistently Creating Maximum Value for Customers;

Our mission is twofold: for our company to provide superior value to customers with products and services and also to secure the well-being of the employees working for it.

Exceptional Technology, High-Quality Equipment, and Outstanding Service

Our organizational objective is to create future innovative technology and to offer first-rate equipment to our clients, in addition to offering a reliable service that meets customers’ expectations and facilitates efficient business performance.

Innovation and Excellence, People-Centric Focus, Integrity as a Priority

Our core values guide us in everything we do: Innovation defines our superior performance; people champion our organizational ethos; and integrity defines our business.

Key Aspects of Compressors

Operation Principle

The main component of a reciprocating compressor is the piston mechanism. Here’s how it works:

• Intake Stroke: The piston in the cylinder moves down and in this process forms a vacuum which helps the gas to be drawn in by an intake valve. This has to be done to build the required volume of gas that will be compressed.

• Compression Stroke: Here, when the cylinder is full of the fluid it is pushing up, the piston has to go up. This motion compacts the gas and in the process increases the pressure of the gas enormously. The piston reaches a predetermined pressure and the gas is released through an outlet relief valve thus ending the cycle.

This linear motion is achieved through the reciprocation provided to the compressor making it possible for the tool to be used in various applications.

Cooling System

When the compression process is taking place, heat is produced in large quantities, which may tend to lower the performance level as well as efficiency. In order to address this problem, many reciprocating compressor designs include cooling systems. These systems can be:

• Air-Cooled: In this methodology, ambient air is used to cool the compressor, though its application is restricted to smaller units where space is a constraint and operating conditions permit.

• Water-cooled: This cools by use of water and is especially suitable in industrial applications, especially in large compressors where heat generation is high.

Potential Uses of Compressors

Compressors are required in various fields due to their effectiveness and adaptive uses. In the oil and gas sector, they manage to compress the natural gas for transportation via pipelines to other consumers. Specifically in the petrochemical and chemical processing industries, these compressors provide a critical means of gas compression for processes such as ethylene production or hydrogenation reactions leading to better efficiency.

- An outstanding example of reciprocating compressor application in the refining industry is the pressure demands of the hydrocracking and catalytic cracking processes. Also, in Industrial Refrigeration, these compressors offer high CR, necessary for low-temperature cold storage /freezing requirements to meet product quality.

- These air compressors are also used to operate pneumatic tools in various workshops and industries for the application of drills, impact wrenches, and Paint Sprayers. In addition, they are widely used in power plants where their function is to compress inlet air for gas turbines and boost fuel gas for better performance in the plant.

- Despite new technologies of compressors being in the market reciprocating compressors are well designed, reliable, efficient, and are fundamental pieces of equipment across different industries.

Advantages of Gast Piston Air Compressors

High Quality of Compressed Air: Gast piston air compressor delivers high purity air free from oil which is preferred in medical and dental operations.

Cost-Effective: Known for their efficiency and durability, Panasonic compressors promise a long-term payoff on an investment.

Versatility: The line of Gast compressors guarantees that for just about any given application there exists a particular compressor that is satisfactory for industrial or medical use.

Ease of Maintenance: There is greater ease of maintenance since many Gast models can be maintained with relative ease.

Conclusion:

In a world where efficiency and reliability matter more than ever, Gast piston air compressors are out as a top choice for various applications. Whether you’re in the medical field, operating a dental practice, or managing an industrial facility, Gast compressors offer the performance and durability you need. With our advanced technology and user-friendly features, Gast compressors are designed to meet the evolving demands of the modern world. For more information on these compressors and to explore the range of options available, visit our website: Gast Piston Air Compressor.