Everything You Need to Know About Tandem Piston Compressor

The Power and Precision of Tandem Piston Compressors:

Compared to other types of high-performance compression systems, but tandem piston compressor is an outstanding performer in terms of efficiency and reliability. These machines which possess two cylinders provide excellent performance in numerous industrial and business operations. As a part of this in-depth article, let us look at every detail of this piston compressor, its features, and its usage.

An Introduction to Tandem Piston Compressor

In its simplest form, a tandem piston compressor is as described a reciprocating compressor that has two cylinders connected to work in parallel to compress air or a gaseous substance. This design is aimed at increasing performance by increasing efficiency and decreasing stress on operational cylinders.

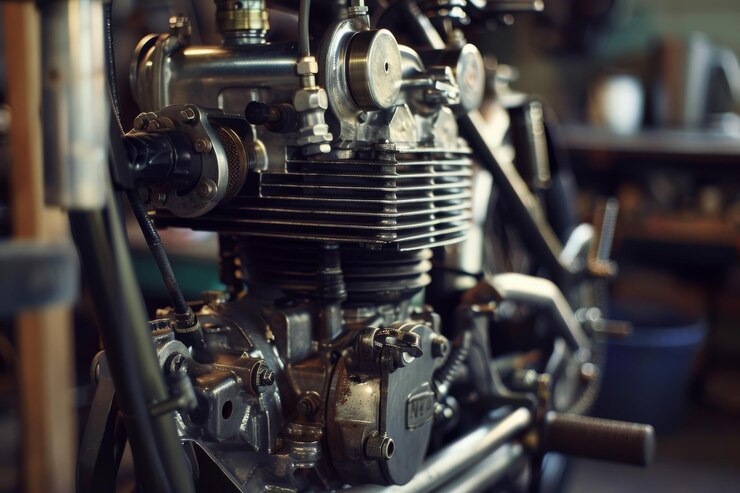

Key Components of a Tandem Piston Compressor

To understand how a tandem piston compressor works it is necessary to consider the main parts of this machine. Each part plays a crucial role in the compressor’s overall function:

• Crankcase: Conceals the crankshaft and offers support to the pistons of the engines.

• Piston: Reciprocates back and forth in the cylinder to compress the air or the gas to be used.

• Piston Rings: Close the pistons, so that there is the least amount of leakage of compressed air.

• Connecting Rod: It connects the piston to the crankshaft.

• Crankshaft: Transfers the rotational movement into a reciprocating type of movement of the pistons.

• Valves: Regulate the admission and release of air gas or mixture within the cylinder.

• Cylinder Head: This is the top of the cylinder and it has the valves enclosed in it.

How Does it Work?

A tandem piston compressor operates through a series of strokes:

Suction Stroke: The piston reverses its motion and travels downward thereby sucking air or the said gas into the cylinder.

Compression Stroke: The piston will now move upwards thus compressing either air or the gas in the cylinder.

Power Stroke: The piston or the head of the cylinder forces the compressed air to come out of it.

Exhaust Stroke: The ozone trapped inside the cylinder has to be removed, in case any is left in the cylinder.

These steps of strokes are of paramount importance in the compressor especially when delivering compressed air or gas continuously.

What Advantages of using LEiYAO Tandem Piston Compressors?

Dual-acting piston compressors have very many advantages as shown above hence making them suitable for use on many occasions. Here’s why LEiYAO is favored in many industries:

High Efficiency: It also highly benefits from the tandem design by which the workload on the two cylinders is more efficiently distributed. This enhances capacity utilization and at the same time brings down the workload on each part. Reliable Performance: These compressors are known to be very strong and resistant which makes them reliable mainly because of their frequent usage in many industries. They are equally stressed and made from high-quality materials which make them perform for a long time.

Versatility: These compressors allow for high pressure, and low pressure as well as are highly versatile in usage. Regardless of whether it will be used for industrial purposes or business purposes, they are elastic enough to fit the requirements of the user.

Energy Efficiency: Most of the contemporary tandem piston compressors are energy-friendly, and their usage minimizes overall working expenses and footprint.

Uses of Tandem Piston Type Compressors

Tandem piston compressor finds wide and versatile applications in different industrial applications because of their unique advantage of reliability. Here are some key applications:

Industrial Applications

In industrial applications, the tandem piston compressor finds its application in compressing air for equipment and production line use such as pneumatic tools and machinery. Due to these qualities, they are very suitable for such tasks which may involve meeting many high-pressure requirements.

Commercial Use

In commercial operations, these Compressors can be used by automotive repair shops, refrigeration units, and HVAC systems. Because of their durability and efficiency, they are some of the most chosen products.

Oil and Gas Industry

In the oil and gas industry, it is common to use high-pressure tandem piston compressors for processes that need large amounts of pressure. They are designed to withstand the working conditions which are characteristic of this industry.

Refrigeration

In refrigeration systems, the twin-piston compressor is used to keep pressure in check to regulate the cooling devices appropriately.

Tips for Maintenance and Care

Tandem piston compressor needs to be maintained properly to optimize its useful life as well as its efficiency. Here are some tips for keeping your compressor in top shape:

Regular Inspections: Ask the owner about the working history of the car and do a routine check to see if there are signs of wear and tear on the piston rings, valves, and crankshaft.

Lubrication: Check that free surfaces are lubricated to avoid friction and wear of these components. This entails such things as checking and putting in new oil when it is required.

Cleaning: Regular maintenance is more important to ensure that the compressor does not get dirty as this might reduce its efficiency of operations. Air filters should also be cleaned frequently and checked to know if there are any blockages.

Check for Leaks: Check whether there are any signs of leakages on the compressor either in terms of air or in terms of gaseous losses.

Professional Servicing: In case of any complicated problem, it is recommended that a professional should be used for service and repairs. It is worth noting that routine professional cleaning can go a long way in addressing some problems before they get out of hand.

How to Select the Correct Tandem Piston Compressor?

Thus, the choice of the proper tandem piston compressor depends on the requirement of a specific application, the amount of pressure required, and the physical conditions where it is to be used. Here are some considerations:

Pressure Requirements: For this purpose, decide whether it would be necessary to use a high-pressure or a low-pressure tandem piston compressor.

Size and Capacity: Therefore, select the correct size and compression capacity regarding your workload.

Energy Efficiency: Select the models that are efficient given energy consumption such that the operational costs will be low.

Brand and Manufacturer: Choose brands and manufacturers who have good records of providing quality units and have good after-sales support. If you have more information about finding quality tandem piston compressors, please visit China Compressors.

Conclusion:

The tandem piston compressor is a testament to engineering excellence, combining efficiency, reliability, and versatility. Our unique design and robust performance make them suitable for a wide range of applications, from industrial settings to commercial uses. For further details on tandem piston compressors and to explore high-quality options, check out LEiYAO. Whether you’re looking to replace an old unit or invest in a new one, this resource offers valuable insights and products tailored to your needs.