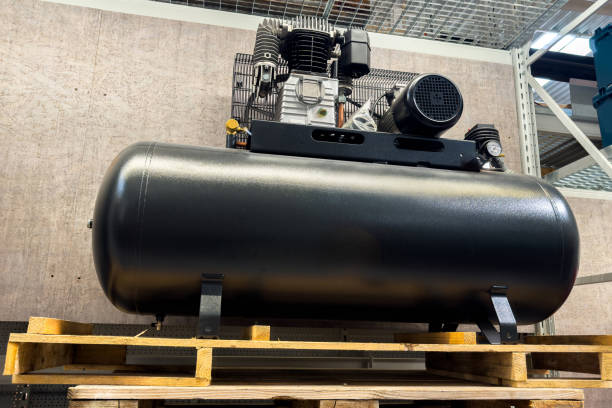

Buyer’s Guide: natural gas powered air compressor

The Powerhouse of Industry: Unleashing the Potential of Natural Gas Powered Air Compressor

As industrial efficiency and environmental responsibility become increasingly important, natural gas powered air compressor is starting to show up as a strong contender to replace conventional electric and diesel-fuelled units. So, what is it about these air compressors that appeals to people so much? This thorough guide dives into the world of these compressors, examining the advantages, uses, and important factors to take into account when making a decision.

Understanding the Power Within: How Natural Gas Powered Air Compressors Work

Fundamentally, these compressors work similarly to their diesel and electric equivalents. They bring in outside air, compress it to a greater pressure, and then distribute it for use in a variety of industrial applications using a screw or piston mechanism. The power supply is where the main distinction is found, though. Natural gas-fueled combustion engines power the compression process in these compressors.

Here’s a breakdown of the working principle:

- Intake:

Air is drawn in from the surrounding environment by the piston or screw mechanism.

- Compression:

The air is compressed by the piston or screw mechanism, greatly raising the air pressure.

- Combustion:

The engine’s natural gas is lit, producing pressure and heat that moves the piston or screw mechanism.

- Discharge:

After being compressed, the air is let out and sent via a system of pipes to the intended location.

- Cooling System:

The engine and compressed air run at different temperatures thanks to an internal cooling system.

Benefits of Natural Gas Powered Air Compressors: A compelling proposition for industry leaders

Air compressors fuelled by natural gas have several benefits that can greatly affect your industrial operations.

- Enhanced Efficiency:

Because natural gas is less expensive than electricity, these compressors may achieve better efficiency when compared to electric ones. They also do away with the energy losses that come with transmitting power.

- Decreased Emissions:

Because natural gas burns cleaner than diesel, it releases fewer toxic pollutants into the air, such as nitrogen oxides and particulate matter. This may make a big difference in your company’s environmental compliance and sustainability goals.

- Cost and Availability of Fuel:

Compared to diesel fuel, natural gas is often less expensive and more widely accessible. This might result in lower total operating expenditure costs for you.

- Performance and Dependability:

Modern air compressors are appropriate for demanding industrial applications because of their remarkable power production and dependable operation.

- Quiet Operation:

Compared to diesel engines, natural gas engines typically run at lower noise levels, giving your staff members a more comfortable workplace.

- Portability:

These compressors may be used in a variety of industrial situations due to their fixed and portable designs.

Industrial Uses: Where Air Compressors Powered by Natural Gas Thrive

Natural gas-driven air compressors provide strong performance and are versatile enough to be used in many different industrial applications. These applications include:

- Construction:

Providing power for pneumatic equipment such as paint sprayers, sanders, and nail guns.

- Manufacturing:

Providing compressed air to assembly lines, cleaning procedures, and machines.

- Oil and Gas Exploration:

Supplying air for instrument operation, pipeline maintenance, and well drilling.

- Tire Inflation:

Tire inflation refers to the process of inflating tires on heavy gear and vehicles used in the transportation, mining, and construction sectors.

Are natural gas-powered air compressors more efficient?

Natural gas powered air compressor may be more efficient than electric ones depending on several variables, however, this is not always the case. Here is a summary to think about:

Advantages of Natural Gas Efficiency:

- Fuel Cost:

In general, natural gas is less expensive than electricity. Lower operational expenses per unit of compressed air generated result from this.

- Transmission Losses:

When electricity is transferred from power plants to your site, part of its efficiency is lost. Since natural gas doesn’t suffer from these losses, its total efficiency may be better.

Natural Gas Efficiency Considerations:

- Engine vs. Motor Efficiency:

Although natural gas burns cleaner, an air compressor driven by natural gas may have an internal combustion engine that is somewhat less efficient than an air compressor powered by electricity.

- Heat Generation:

During combustion, natural gas engines produce heat. A certain amount of energy is wasted throughout the cooling process.

Maintaining the Powerhouse: Essential Care for Natural Gas Powered Air Compressors

Workhorses in many sectors, natural gas powered air compressor provides dependable compressed air. However, for maximum performance and lifespan, like with any powerful equipment, adequate maintenance is essential. The following is a summary of the essential upkeep needed to maintain the smooth operation of this compressor:

Routine Maintenance:

- Air Filter Changes: Change your air filters regularly to maintain a clean intake of air and stop internal component wear. (Recurrence is dependent on environment and usage.)

- Oil and Oil Filter Changes: To lubricate moving parts and get rid of impurities, replace oil and oil filters according to the manufacturer’s suggested timetable.

- Drain Condensation: The compressed air tank may get too wet. To guarantee effective operation and avoid corrosion, drain the condensate regularly.

- Visual Exams: Check the compressor regularly for wear and tear, leaks, and loose connections. Respond quickly to any problems.

Scheduled Maintenance:

- Spark Plug Replacement: To guarantee correct engine ignition and performance, replace spark plugs at the manufacturer’s recommended intervals.

- Valve Adjustments: To retain the best possible compression efficiency over time, valves may need to be adjusted. When scheduling valve adjustments, according to the manufacturer’s guidelines.

- Cooling System Maintenance: To guarantee adequate heat dissipation and avoid engine overheating, clean the cooling system’s air filters and radiators.

Additional Tips:

By following these maintenance procedures, you can extend the life, effectiveness, and performance of this compressor and maintain the smooth functioning of your industrial processes.

- Consult the handbook: For detailed maintenance plans and instructions, always consult the user handbook that comes with your air compressor.

- Spend Money on Training: Appropriate operator training can help minimize costly errors and make a major contribution to preventative maintenance.

- Join Forces with a Reputable Service Provider: Plan for routine maintenance by a licensed specialist to guarantee thorough upkeep and spot possible problems before they become more serious.

Conclusion:

Our firm, LEiYAO Compressors, has a wealth of design and production experience and is outfitted with cutting-edge technical testing facilities and procedures. We provide our global customers with all-inclusive, one-stop solutions while guaranteeing great product quality and first-rate service.