Argon Compressor: A Comprehensive Guide

Introduction

Argon compressor play a crucial role in various industries, and this comprehensive guide is here to shed light on their importance, working principles, applications, components, selection factors, manufacturers, case studies, future trends, and more. Let’s dive into the world of argon compressors.

Working Principles of Argon Compressors

Argon compressors work by compressing argon gas to higher pressures, making them essential for many industrial processes. There are two main types of argon compressors: Positive Displacement Compressors and Dynamic Compressors. Positive Displacement Compressors use mechanical displacement to increase pressure, while Dynamic Compressors rely on kinetic energy. Understanding these principles is vital for selecting the right compressor for your needs.

Industrial Applications of Argon Compressors

Argon compressors find applications in diverse industries. In the metal industry, they are used for argon arc welding and heat treatment, ensuring high-quality metal products. Electronics and semiconductor manufacturing benefit from argon compressors in creating cleanroom environments and ion implantation processes. Scientific and research applications, including particle accelerators and cryogenic laboratories, also rely on argon compressors for their experiments and studies.

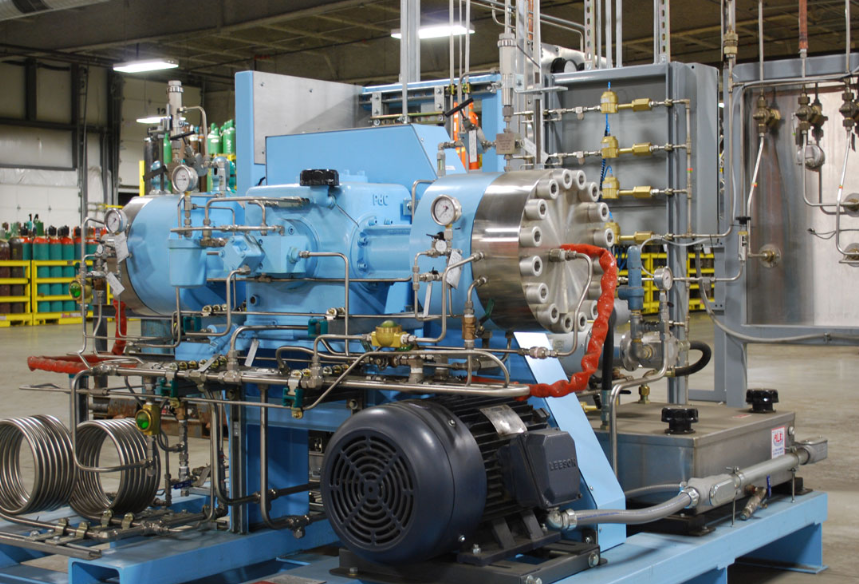

Key Components of Argon Compressors

To understand argon compressors better, let’s explore their key components. Compressor units are the heart of these machines, responsible for gas compression. Cooling systems are equally important, as they maintain the compressor’s temperature and efficiency. Control and safety systems ensure safe operation by monitoring various parameters. Knowing these components will help you make informed decisions when choosing an argon compressor.

Factors to Consider When Selecting an Argon Compressor

When selecting an argon compressor, several factors come into play. Capacity and pressure requirements should align with your specific needs. Material compatibility ensures that the compressor is compatible with the gases it handles. Energy efficiency reduces operational costs, while considering maintenance needs is essential for long-term reliability.

Leading Manufacturers and Models of Argon Compressors

Explore prominent manufacturers and their highlighted compressor models. Each manufacturer may offer unique features and advantages, making it crucial to choose the right one for your application. Knowing the leading players in the industry will guide your decision-making process.

Case Studies

Real-world case studies showcase the practical applications of argon compressors. Success stories and performance enhancements demonstrate the positive impact these machines have had in various industries. Learning from these examples can inspire you to harness the potential of argon compressors in your field.

Future Trends in Argon Compressors

The world of argon compressors is ever-evolving. Innovations in compressor technology and sustainable practices are shaping the future of argon compression. Integration with advanced manufacturing processes is on the horizon, promising even more efficient and environmentally friendly solutions.

Conclusion

In conclusion, argon compressors are indispensable tools in multiple industries, ensuring the reliable handling of argon gas. This comprehensive guide has demystified their working principles, highlighted their applications, and provided insights into selecting the right compressor for your needs. As we move forward, argon compressors will continue to play a pivotal role in industry and research, driving innovation and progress. Explore their potential, and unlock new possibilities in your field with argon compression solutions.