A Comprehensive Guide to Unloading Compressor

Unloading compressor are integral components in various industries, playing a pivotal role in processes that require compressed air or gases. These versatile machines are designed to adjust their capacity to match the specific needs of a system, ensuring efficient operation while minimizing energy consumption. In this comprehensive guide, we will delve into the world of unloading compressors, exploring their types, applications, working principles, advantages, maintenance practices, and emerging trends.

Introduction to Unloading Compressor

An unloading compressor is a mechanical device used to compress air or gases by reducing the pressure inside a closed chamber. What distinguishes unloading compressors from their constant-speed counterparts is their ability to modulate their capacity according to the system’s demand, thereby optimizing energy usage.

Unloading compressors hold significant importance in a wide range of industries, including manufacturing, HVAC, refrigeration, and the oil and gas sector. Their ability to provide compressed air efficiently makes them indispensable for various processes, from powering pneumatic tools to maintaining precise environmental conditions.

Unloading compressors operate on the principle of load and unload cycles. When the compressed air demand is high, the compressor operates at full capacity, providing the required airflow. However, during periods of reduced demand, the compressor unloads or reduces its capacity to avoid wasteful energy consumption. This modulation of capacity is achieved through control mechanisms that vary depending on the compressor type.

Types of Unloading Compressor

Working Principle

Reciprocating unloading compressors use pistons to compress air. During the load cycle, the piston compresses air into a cylinder. In the unload cycle, the inlet valve is closed, allowing the compressor to bypass air, reducing its capacity.

Advantages and Disadvantages

Reciprocating compressors are known for their durability and ability to handle high pressures. However, they can be noisy and less energy-efficient compared to other types.

Rotary Screw Unloading Compressors

Working Principle

Rotary screw unloading compressors employ two interlocking helical screws to compress air. The compression process is modulated by adjusting the distance between the screws to control airflow.

Advantages and Disadvantages

These compressors are known for their high efficiency and reliability. They operate quietly but may require higher initial investment.

Centrifugal Unloading Compressors

Working Principle

Centrifugal unloading compressors use a high-speed impeller to accelerate air and then slow it down to increase its pressure. Capacity modulation is achieved by varying the speed of the impeller.

Advantages and Disadvantages

Centrifugal compressors are suitable for high-capacity applications and are energy-efficient. However, they are sensitive to changes in inlet conditions and may require precise control.

Applications of Unloading Compressors

Unloading compressors are vital in industrial manufacturing processes, where they power pneumatic tools, control air quality, and assist in material handling.

In HVAC systems, unloading compressors regulate temperature and humidity, ensuring optimal indoor comfort in residential, commercial, and industrial buildings.

Unloading compressors are the heart of refrigeration systems, maintaining low temperatures for food storage, transport, and industrial refrigeration applications.

In the oil and gas sector, unloading compressors are used for gas gathering, transmission, and injection processes, enhancing production efficiency.

Key Components of Unloading Compressors

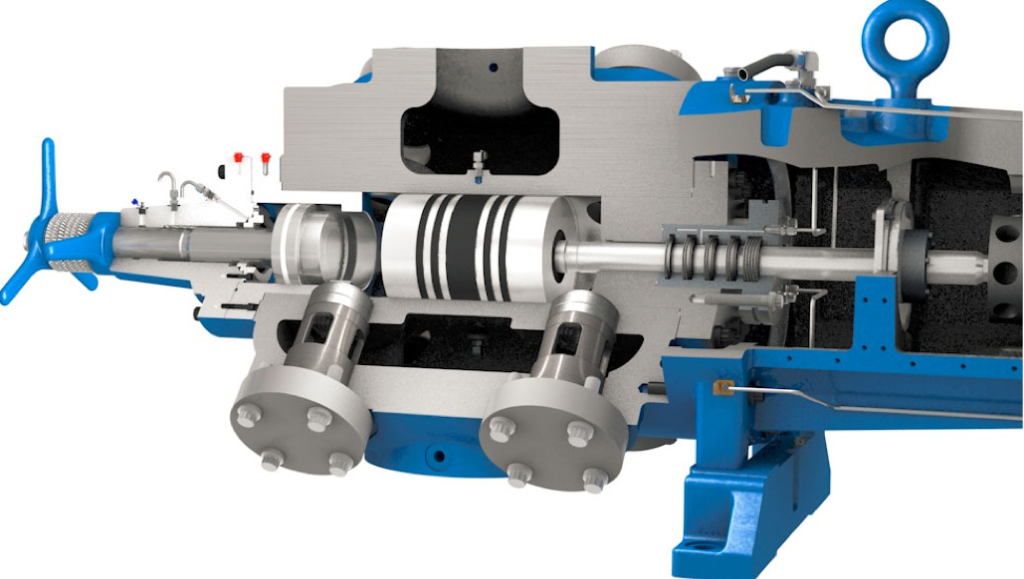

The compressor unit consists of the mechanical components responsible for compressing air or gases. It includes the compressor housing, pistons or screws (depending on the type), valves, and the drive mechanism.

Control mechanisms vary based on the compressor type but generally involve sensors, valves, and a control panel. These components work together to monitor system demand and adjust compressor capacity accordingly.

Unloading compressors require lubrication to reduce friction and cooling systems to dissipate heat generated during compression. Proper maintenance of these systems is crucial for compressor longevity.

Working Principles of Unloading Compressors

Unloading compressors adjust their capacity by either changing the speed of the compressor (centrifugal) or altering the compression process (reciprocating and rotary screw) to match the demand for compressed air or gases.

The ability to unload or reduce capacity during low-demand periods significantly enhances energy efficiency, resulting in reduced operational costs and environmental benefits.

Load and unload cycles ensure that the compressor operates efficiently, avoiding unnecessary energy consumption. This cyclic operation is facilitated by control mechanisms.

Advantages and Benefits of Unloading Compressors

Unloading compressors excel in energy efficiency, as they only consume the energy required to meet the system’s demand. This leads to substantial energy savings over time.

Efficient modulation of capacity and reduced wear and tear during low-demand periods contribute to a longer compressor lifespan.

Unloading compressors enhance system reliability by maintaining consistent pressure and airflow, reducing the risk of downtime and production disruptions.

The ability to precisely control compressor capacity allows for better system performance and responsiveness to changing demands.

Considerations for Selecting Unloading Compressors

Understanding the specific needs of your application, including required capacity and pressure levels, is crucial for selecting the right unloading compressor.

Consider the environmental conditions, space constraints, and any unique requirements of your application when choosing a compressor type.

Evaluate not only the initial purchase cost but also the long-term operating and maintenance costs to make an informed decision.

Maintenance and Safety Practices for Unloading Compressors

Regular maintenance, including lubrication, filter replacement, and system checks, is essential to ensure the continued reliability and efficiency of unloading compressors.

Compressor operators should follow safety protocols and receive proper training to prevent accidents and ensure a safe working environment.

Adherence to industry standards and regulations is critical to maintain safety and environmental compliance when using unloading compressors.

Emerging Trends in Unloading Compressor Technology

The integration of smart technology and the Internet of Things (IoT) in compressors allows for real-time monitoring, predictive maintenance, and remote control, enhancing operational efficiency.

As environmental concerns grow, the use of eco-friendly refrigerants in unloading compressors is gaining traction, reducing the carbon footprint of cooling and refrigeration systems.

Unloading compressors are increasingly integrated into comprehensive energy management systems, optimizing energy usage and reducing operational costs.

Conclusion

In conclusion, unloading compressors are vital components in numerous industries, providing energy-efficient compressed air and gases for various applications. Their ability to modulate capacity, coupled with advances in technology, continues to revolutionize energy efficiency and industrial processes. As we look to the future, smart and eco-friendly innovations promise to further enhance the role of unloading compressors in our ever-evolving industrial landscape. Embracing these technologies will not only unlock significant energy savings but also contribute to a more sustainable and environmentally friendly future.