Unloading Compressors: Key to Efficient Storage and Distribution Systems

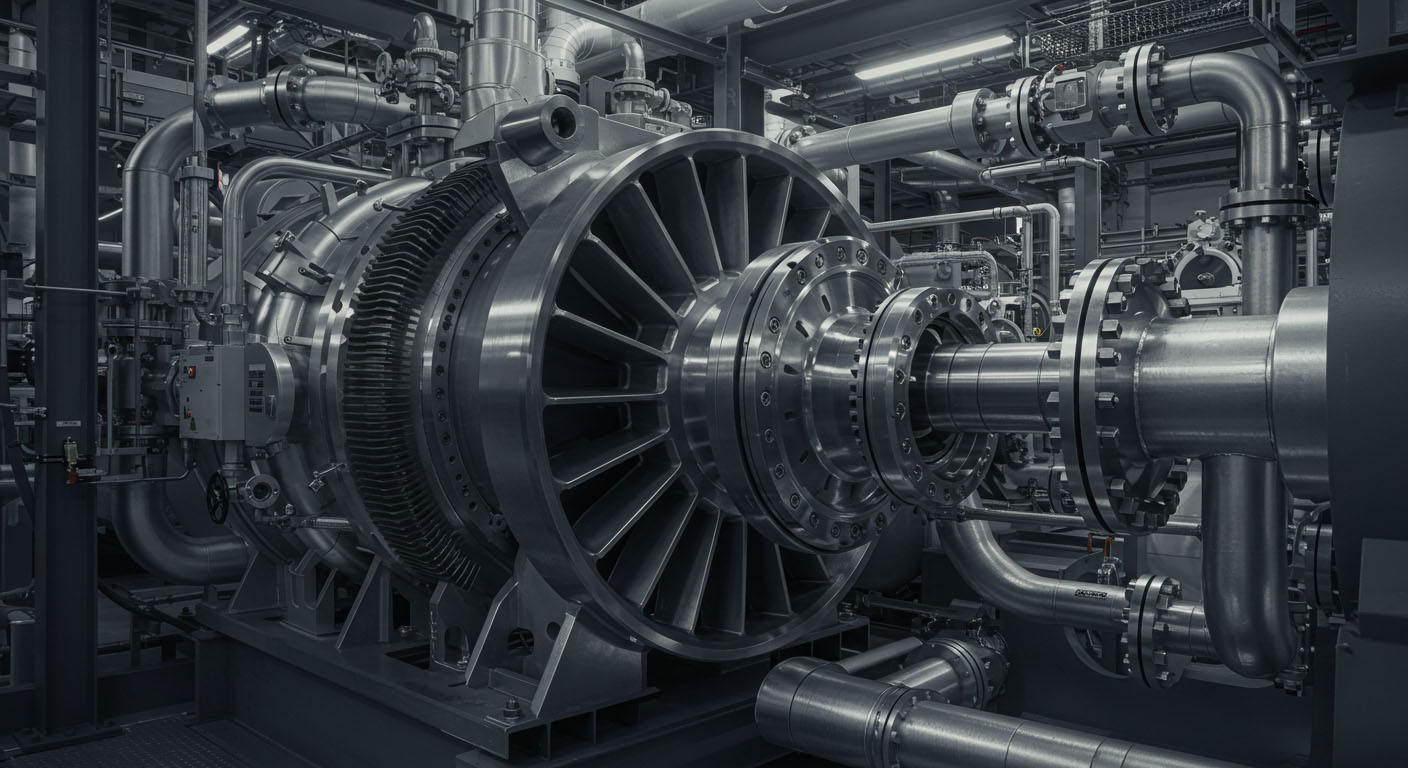

In the industrial and commercial sectors, unloading compressors play a crucial role in ensuring the smooth operation of systems that involve the transfer, storage, and distribution of gases and liquids. These compressors are designed to unload compressed air or gas from storage tanks, pipelines, and vessels, making them essential components in applications ranging from manufacturing plants to energy facilities. In this blog, we’ll explore what unloading compressors are, their primary functions, and how they improve the efficiency of industrial systems.

What is an Unloading Compressor?

An unloading compressor, also known as a gas unloading compressor, is a specialized type of compressor used to reduce pressure in a system by discharging the stored gas or liquid from a pressure vessel or tank. This process is crucial for maintaining optimal operational pressure, reducing stress on equipment, and ensuring smooth transitions during operations.

Typically, unloading compressors are used in industries where gas or liquid is stored in high-pressure tanks, pipelines, or vessels, such as in natural gas storage, chemical processing, energy production, and compressed air systems. These compressors operate by unloading compressed air or gases from storage into the pipeline or other infrastructure, ensuring a consistent and controlled flow of materials.

Importance of Unloading Compressors in Industrial Systems

Unloading compressors serve several key functions in industrial operations. Here are some of the primary reasons why they are essential for a variety of industries:

1. Maintaining Optimal Pressure

Many industries rely on maintaining consistent pressure levels in their systems for efficient operations. Unloading compressors are designed to relieve pressure by unloading stored gas or air, ensuring that the pressure does not exceed safe limits. This is particularly important in industries such as natural gas storage, where excess pressure can lead to dangerous leaks or ruptures in pipelines.

2. Energy Efficiency

Unloading compressors are designed to maximize energy efficiency by discharging compressed air or gas at the required pressure and flow rates. These compressors help to minimize energy consumption, reduce operational costs, and improve overall system efficiency.

3. System Protection

Unloading compressors protect the integrity of storage tanks, pipelines, and vessels by preventing excessive pressure buildup, which could cause equipment failure or damage. By providing controlled unloading of gases, these compressors reduce the risk of equipment failure, ensuring continuous operations.

4. Facilitating Safe Transport and Storage

In industries such as oil and gas, chemical production, and compressed air systems, unloading compressors make it easier to safely transport and store compressed gases. Unloading systems allow for the proper distribution of gases and liquids, ensuring that materials are safely transferred to different parts of the facility or transported to external locations.

Applications of Unloading Compressors

Unloading compressors find applications in a variety of industries. Below are some of the most common applications:

1. Natural Gas Storage and Distribution

In natural gas storage, compressors are used to offload or unload gas from high-pressure storage tanks. This ensures that the gas can be transferred to pipelines or distribution systems at a safe, controlled pressure. Unloading compressors are critical in gas storage facilities where gas is stored under high pressure and must be carefully managed to prevent over-pressurization.

2. Chemical Processing Plants

In chemical plants, unloading compressors are used to discharge pressurized gases from reactors and tanks. By maintaining optimal pressure levels, unloading compressors help facilitate the safe storage, transportation, and handling of gases involved in chemical processes. Whether it’s unloading compressed hydrogen, methane, or ammonia, these compressors are crucial for maintaining operational efficiency and safety.

3. Energy Production and Power Generation

In energy production facilities such as natural gas power plants, unloading compressors are employed to unload stored natural gas from tanks to maintain consistent gas flow to turbines or engines. Proper unloading is necessary to ensure that the right amount of gas is delivered to power generation equipment, helping maintain stable energy production.

4. Compressed Air Systems

In many industries, compressed air is used for various applications like powering pneumatic tools, packaging, or industrial automation systems. Unloading compressors are used to unload compressed air from storage tanks and ensure consistent air pressure throughout the system, reducing the risk of energy waste and equipment downtime.

5. Refrigeration Systems

Unloading compressors are also used in refrigeration systems that use gases like ammonia or CO₂ as refrigerants. In these systems, compressors unload gas from high-pressure storage containers to regulate pressure and maintain efficient cooling operations.

Technological Advancements in Unloading Compressors

The evolution of unloading compressor technology has improved efficiency, performance, and safety. Some of the latest advancements include:

1. Variable Speed Drives (VSD)

Unloading compressors with variable speed drives (VSDs) can adjust their speed according to the required pressure and flow conditions. This helps optimize energy usage and allows the compressor to operate more efficiently under varying loads. VSD technology also reduces wear and tear, extending the lifespan of compressors.

2. Advanced Control Systems

Modern unloading compressors are equipped with sophisticated control systems that can monitor and adjust system parameters in real-time. These systems help optimize compressor performance, predict maintenance needs, and prevent potential failures by alerting operators to anomalies before they become critical issues.

3. Smart Monitoring and Diagnostics

With IoT integration and remote diagnostics, unloading compressors can be monitored in real-time to ensure optimal performance. Sensors and analytics can track compressor health, pressure levels, and energy usage, helping operators make informed decisions and reduce maintenance costs.

Conclusion

Unloading compressors are vital to the smooth and efficient operation of gas storage, chemical processing, and energy production systems. By maintaining optimal pressure, ensuring energy efficiency, and protecting equipment integrity, these compressors contribute to the overall safety and success of industrial operations. With advancements in compressor technology, industries can now benefit from more efficient, reliable, and sustainable unloading solutions.

At LEiYAO Compressors, we specialize in delivering state-of-the-art unloading compressors designed to meet the unique needs of various industries. Our products combine cutting-edge technology with unparalleled reliability, ensuring that your operations remain efficient and safe.