Maximizing Performance With Power Generation Screw Compressor

Unlocking Efficiency in Industrial Energy Solutions with Power Generation Screw Compressor:

In the ever-changing world of industries, one can view power generation as the basis through which many undergo important developments. As many industries such as oil and gas, manufacturing plants and construction require power for their operations and production, there is a need for proper and efficient power. This is where the Power Generation Screw Compressor comes in; the machine that has transformed industries energy utilization. In this article, you will learn more about these compressors and why should be considered as one of the best compressors to have, the benefits and uses of these compressors and the different types of them in a conversational tone that will suit your wants and needs.

Knowing the Power Generation Screw Compressor

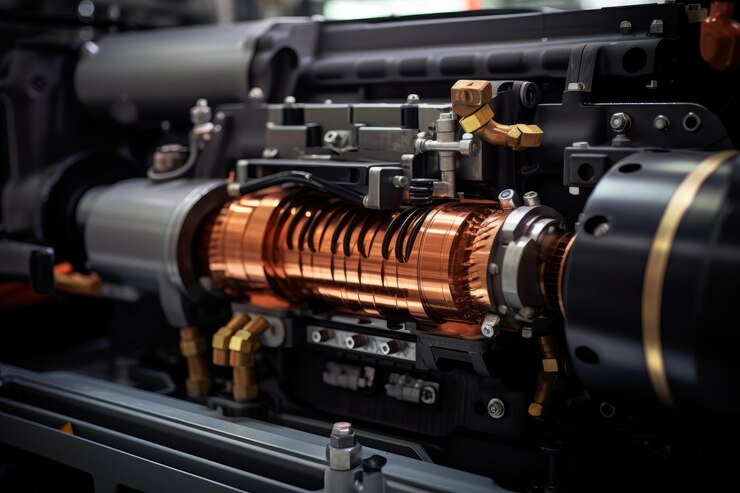

A power generation screw compressor is not merely an apparatus; it is the pulse of several industries across the world. In its basic form, a screw compressor entails the use of two interfacing helical screws referred to as rotors to compress gases. The design makes it possible for there to be a constant flow of compressed air or gas and this makes it appropriate for operation where a constant supply of power is necessary.

Features of Power Generation Screw Compressors:

In the field of industrial power generation, the Power Generation Screw Compressor presents itself as a rather useful and efficient tool. These compressors have been manufactured to provide solutions to your operations needs as they are developed to withstand the demands of different industries. Now it is time to discuss the major peculiarities that define these compressors as optimal for power generation.

- Continuous Operation:

Another advantage discerned with screw compressors is a contingency of continuous operation. Unlike other forms of compressor that may in some cases need to be cycled on and off more often, screw compressors provide a constant supply of elements compressed air. This implies that your industrial processes; in manufacturing, construction or power generation will always have a steady supply of electricity.

- High Efficiency:

Screw compressors are usually a favourite in any industrial environment due to their high efficiency. These compressors work at the best compression ratios hence cutting much on energy usage and thus the operating expenses. Screw compressors are therefore the most effective for industries seeking to make a change towards energy-efficient units which will help to reduce their emission of carbon.

- Compact Design:

Most industrial environments have limited or limited amounts of space in which equipment and people can move and work. Fortunately, screw compressors are usually developed with a small profile so that they can fit in places that have limited space. These compressors however come in small sizes yet they do not lack any power and efficiency like in small spaces.

Variable Speed Control

The latest technology that is available in modern screw compressors includes the variable speed drive, also known as VSD. This technology enables the compressor to run at different speeds depending on the amount of compressed air required in an organization. In this way, the application’s precise power demands are met through the operation of the VSD, thus enhancing the energy efficiency of the compressor and decreasing material stress on the machine and compressor, therefore prolonging the compressor’s service life.

What Benefits Come with Utilizing Screw Compressors from LEiYAO Power Generation?

- Low Noise Levels:

Screw compressors are designed to function in industrial settings, and although such environments can be rather noisy, these particular machines minimize that problem. Our compressors have low noise due to the design of the helical rotor used in the construction of the equipment. The first two advantages are associated with smooth airflow and low vibration, and they make a difference especially where noise has to be minimized to protect workers.

- Durable Construction:

Screw-type power generation compressors are designed for heavy-duty operations inherent with power generation applications and as such are constructed from strong materials. Our compressors are built to run for a long time in extreme conditions, and constant use; this reduces the chances of breakdowns which will cause production to come to a standstill.

- Oil-Injected and Oil-Free Options

Screw compressors can be either oil-injected or oil-free depending on the needs of the market and the industry. The oil-injected screw compressor is ideal for general industrial applications since it involves the use of oil in compressed air to a certain extent. Whereas oil-ready screw compressors are used in industries that require high-quality air such as food industries, pharmaceutical and electronics industries.

Easy Maintenance

Reliability and maintenance is key factors in any industrial process and screw compressors have put this into consideration. These compressors have few components and are engineered in such a way that most of them are low on the maintenance scale. These aspects make the construction of the structures cost-effective to use since they do not require constant repair hence lowering the overall cost of using the structures. Pressure Regulation Systems

An industrial environment needs pressure at varying levels depending on the kind of task it is involved in. These compressors are designed with pressure regulation systems that help the user make optimum pressure settings and control functions. This feature makes sure the compressor supplies only the exact pressure of air required to complete a certain operation and, therefore, increases efficiency in addition to the performance of the compressor.

Selecting the Appropriate Screw Compressor for Power Generation Requirements

Therefore, the choice of the power generation screw compressor unit depends on several factors that include the industry type of your plant, application, and energy policies. Here are some tips to help you make the best choice:

- Assess Your Power Needs:

It is important to find out the exact amount of power that is needed by your operations. This will assist you in making the right decision on a compressor that you require for your job. For instance, in a case that involves a high-pressure air or a gas supply then a high-pressure screw compressor may be suitable for use.

- Consider Energy Efficiency:

Electrical power costs can be very high thus the need to select a compressor that is energy efficient. Consider models that incorporate VSD technology or models which are intended for energy saving.

- Think About Maintenance:

It is especially important to pay a lot of attention to the concerns of maintenance. There are differences in the type of compressors for instance oil-free will need less maintenance and easy to maintain. In this regard, be cautious while selecting a compressor that you can maintain effectively and that does not exceed your financial capability.

- Evaluate Environmental Impact:

If sustainability is considered to be a priority, then, a solar-powered or a wind-powered screw compressor should be adopted. Apart from making your carbon footprint smaller, these compressors can save more energy in the long run than the traditional models

Conclusion:

The Power Generation Screw Compressor is a vital tool in various industrial applications, offering unmatched efficiency, durability, and versatility. Whether you’re powering an oil rig, a manufacturing plant, or a renewable energy system, these compressors deliver the reliable performance you need to keep your operations running smoothly.

By understanding the features and characteristics of these compressors, you can select the right model that aligns with your specific needs. For more detailed information and guidance on choosing the right compressor, visit our website at LEiYAO.