Understanding High Pressure Gas Compressor: Types, Applications & More

The Powerhouse of Industry: A Comprehensive Guide to High Pressure Gas Compressor

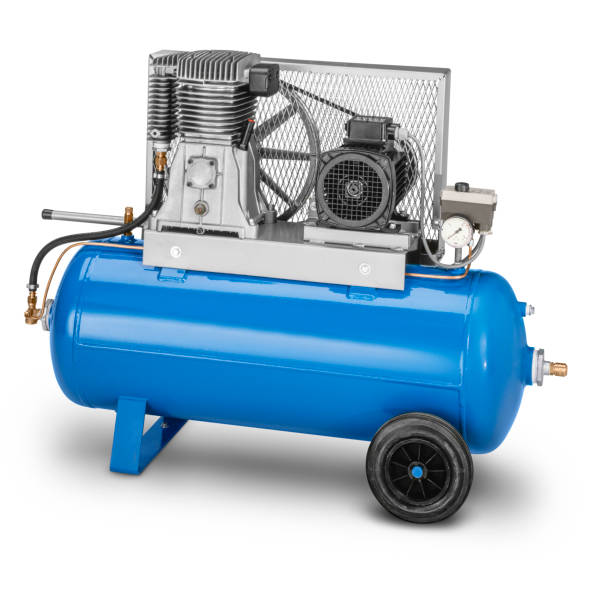

High Pressure Gas Compressor is the hidden heroes of contemporary industry. These incredible devices are essential to a myriad of applications, ranging from power generation to car fuel. However, how do high-pressure gas compressors operate and what are they exactly? This thorough article explores the many forms of gas compression, their uses, and important considerations to make when choosing the best compressor for your requirements.

The Power Behind the Pressure: Why We Need High-Pressure Gas Compression?

Consider the challenge of storing or moving a large quantity of something very light and fluffy, such as cotton balls. That would not be very effective, would it? Gases are no different. They often take up a large amount of area in their natural condition. But what if we had to compress the gas to make it simpler to transport, store, or even power some operations?

High pressure gas compression is useful in this situation. By compressing gas molecules closer together, these amazing devices work like unseen fists, raising the pressure and density of the gas. This compressed gas turns into a powerhouse, facilitating several vital operations in many different sectors.

Why high-pressure gas compression is so important?

- Effective Transportation:

Without compression, pipelines carrying natural gas over long distances would not be possible. More gas may be packed into the pipeline by raising the gas pressure, which improves transportation efficiency and lowers costs.

- Improved Storage:

Compression makes high-pressure gas storage tanks possible. This makes it possible to store gases for use in automobiles, such as compressed natural gas (CNG) or natural gas, safely and effectively.

- Powering Processes:

For several industrial processes to operate properly, gases at particular pressures are needed. Precise transport of these gases is guaranteed by high-pressure compressors, which facilitate everything from chemical reactions in the manufacturing of plastics to effective combustion in power plants.

The Three Main Types of High-Pressure Gas Compressors:

Three main types of compressors are available in the field of high-pressure gas compression, each having unique advantages and uses:

- Reciprocating compressors:

These compressors, also called piston compressors, work by compressing gas with the help of a piston that moves inside a cylinder. They work well with a variety of gas types, such as air, natural gas, and hydrogen, and are capable of reaching high discharge pressures of up to 30,000 psi.

- Centrifugal Compressors:

These fast-moving devices use an impeller to provide the gas kinetic energy, which a diffuser then transforms into pressure. Centrifugal compressors are frequently employed in the processing of oil and gas and the transportation of natural gas, because they are perfect for big-volume gas, flows at moderate pressure ranges (up to 1,500 psi).

- Screw Compressors:

Using intermeshing screws, screw compressors, which are distinguished by their positive displacement design, capture and compress gas? They are appropriate for a variety of industrial applications, such as air compression for pneumatic tools and plastic manufacture, since they provide a good balance between pressure and flow rate.

Powering Industries: LEIYAO as a High-Pressure Gas Compressor Manufacturer:

LEIYAO Compressor is aware of how important high pressure gas compressor is to a variety of sectors. With our proficiency in producing these potent apparatuses, we provide a wide array of high-pressure gas compressors to meet a variety of requirements.

- Emphasis on Innovation:

To assure effectiveness, dependability, and durability, we may be dedicated to ongoing innovation, creating high-pressure gas compressors with state-of-the-art technology.

- Broad Product Offering:

To meet the needs of diverse industries such as oil and gas, chemical processing, and power generation, we may provide a variety of compressor types, such as reciprocating, centrifugal, and screw compressors.

- Customization Options:

To ensure that their compressors precisely meet the demands of our clients, LEIYAO is able to offer customisation options to fit the requirements of certain projects.

- Commitment to Quality:

To provide long-lasting performance and less maintenance requirements, we may give preference to using premium materials and components in their compressors.

- Global Reach:

With the ability to be present everywhere, we might be able to provide high-pressure gas compressor solutions and their knowledge to customers all over the world.

The Invisible Hand of Industry: Unveiling Applications of High-Pressure Gas Compressors

High pressure gas compressor is the unsung heroes of the industrial world, quietly transforming our everyday lives in a myriad of ways. These devices are more than simply pumps; they are the unseen hands that pressurize gases into streams, enabling processes and fostering creativity in a variety of industries. Now let us examine several important applications in which high-pressure gas compressors are essential:

- The Foundation of Oil and Gas:

These compressors are used at every step of the process, from carrying natural gas via lengthy pipes to extracting crude oil from deep under the ground. They guarantee these priceless materials are retrieved, processed, and delivered effectively.

- Chemical Processing Powerhouse:

For best results, chemical processes frequently need a certain gas pressure. The unsung heroes of the chemical industry are high-pressure compressors, which precisely provide gases such as hydrogen, nitrogen, and oxygen for a variety of chemical reactions during the manufacture of plastics, fertilizers, and other necessary chemicals.

- Fueling the Future:

As a cleaner alternative fuel for automobiles, compressed natural gas, or CNG, is becoming more and more popular. The essential actors in the background are high-pressure compressors, which efficiently and safely compress natural gas to the required level for CNG filling station dispensing and secure storage.

- Power Generation Powerhouse:

High-pressure gas compressors are essential to both natural gas-powered turbines and traditional fossil fuel power plants. In the end, these compressors provide the energy that runs our homes and businesses by ensuring that fuel is delivered at the necessary pressure for effective combustion.

- Air Separation with Potential Life-Saving Uses:

Medical-grade oxygen is a necessary and continuous source for hospitals and other medical institutions. In air separation facilities, high-pressure compressors are essential because they compress and clean atmospheric air to separate industrial gases like oxygen, nitrogen, and argon, which are used for several industrial operations as well as medicinal uses.

Selecting the Right High-Pressure Gas Compressor: Key Considerations

It’s important to carefully evaluate several aspects when selecting the best high pressure gas compressor for your particular needs:

- Gas Type:

The characteristics of various gases differ, which affects the choice of compressor. It is important to know what kind of gas you are compressing (air, natural gas, hydrogen, etc.).

- Required Discharge Pressure and Flow Rate:

The compressor’s capacity is determined by the required pressure at the compressor’s output (discharge pressure) and the amount of gas that must be compressed in a given amount of time (flow rate).

- Use:

Selecting the best compressor type is aided by knowing the precise use for the compressed gas. For example, a compressor meant for natural gas transportation is not the same as one needed for high-pressure air needed to power equipment.

- Efficiency:

Especially for continuous operation, energy efficiency is a crucial component. Think about how much electricity the compressor uses and how that affects your running expenses.

- Maintenance Requirements:

For the compressor to operate at its best, routine maintenance is necessary. Consider the selected compressor’s accessibility to replacement parts and simplicity of maintenance.

Seeking help from a reliable manufacturer of high-pressure gas compressors, such as LEIYAO Compressor might be beneficial.

Keeping the Powerhouse Running: Maintaining Your High-Pressure Gas Compressor:

The workhorses of the industry are gas compressors, but like any strong equipment, they need regular maintenance to guarantee lifespan, maximum performance, and safety. The following are some essential upkeep procedures to maintain your high-pressure compressor operating efficiently:

- Frequent Inspections:

Arrange for regular inspections to spot any possible problems early on. This involves inspecting the lubricant’s quality and quantity, looking for leaks, and assessing wear and tear on parts like valves and pistons.

- Oil changes:

Lubricants are essential for lowering friction and safeguarding interior parts. Following the manufacturer’s recommendations for routine oil changes is essential to preserving maximum performance and averting expensive breakdowns.

- Maintenance of Filters:

Oil and air intake filters are essential for shielding the compressor from impurities. The longevity of your compressor may be increased by routinely cleaning or changing these filters, which guarantee clean air intake and appropriate lubrication.

- Maintenance for Aftercoolers:

By removing moisture from compressed gas, aftercoolers help to avoid corrosion and other problems. Optimizing performance and averting any damage is ensured by routinely emptying condensate and checking the aftercooler for leaks.

- Monitoring Performance:

It is possible to spot any issues early on by closely monitoring key performance indicators such as vibration levels, flow rate, and discharge pressure. Costly repairs and downtime can be avoided with early diagnosis and action.

Conclusion:

It’s important to select the best manufacturer for high pressure gas compressor. By potentially highlighting why LEIYAO would be a dependable partner for their high-pressure gas compression wants by perhaps emphasizing the company focus on innovation, varied product range, and dedication to quality. Recall carrying out more investigation to validate this information, particularly to LEIYAO Compressor.