The Ultimate Guide to Choosing the Right 3 Piston Air Compressor

The Potential of Three Piston Air Compressors: Unlocking Their Power

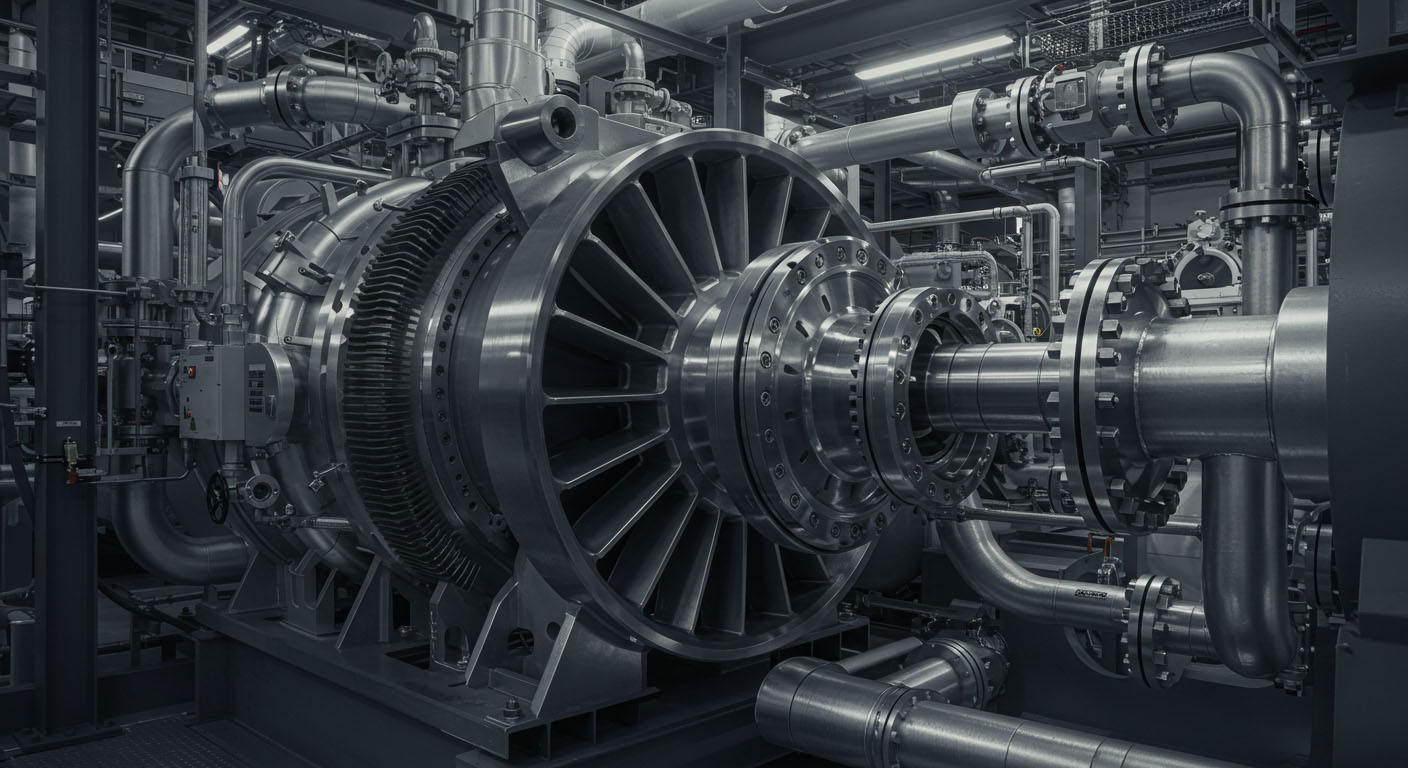

Numerous applications in various industries are powered by the world of compressed air. Air compressors provide a flexible and dependable source of compressed air for a variety of applications, such as tyre inflation, paint sprayer fuel, and pneumatic tool power in the construction industry. In this domain, three-piston air compressors are a notable and effective option for a range of applications.

This thorough guide dives deeply into the world of 3 piston air compressor, examining their features, advantages, uses, and important factors to take into account during selection and upkeep. This article provides you with the information to fully utilize the potential of these durable workhorses, regardless of your level of experience or interest in do-it-yourself projects.

Uncovering the Workings of the Three-Piston Air Compressor

They work by using three pistons that are contained within a cylinder block. The reciprocating action produced by the crankshaft driving these pistons pushes air into the cylinder and compresses it. After that, the compressed air is released into a pressurized tank for later use and storage.

Here’s a summary of the essential elements:

- Pistons:

The compressor’s main component, the pistons, draws in and compresses air by moving back and forth inside the cylinders.

- Cylinder Block:

The cylinder block contains the pistons and offers a sealed space for compressing air.

- Crankshaft:

Transforms the motor’s rotational motion into the pistons’ reciprocating motion.

- Intake Valves:

During the intake stroke, permit new air to enter the cylinders.

- Discharge Valves:

During the compression stroke, direct the compressed air into the receiver tank.

- Air Receiver Tank:

The compressed air is kept in the air receiver tank for subsequent use. Additionally, it gives the compressed air extra cooling and aids in controlling pressure variations.

- Pressure regulator:

This device regulates the air pressure that is sent to the outlet, letting you change it according to the needs of the particular use.

- Safety Valve:

A vital safety device known as a safety valve releases pressure on its own when it rises above a safe level.

Unleash Efficiency and Power: The Advantages of 3 Piston Air Compressors

The 3 piston air compressor is a notable champion of efficiency and versatility in the field of compressed air. This workhorse empowers experts and do-it-yourselves alike with a host of advantages over its single-piston contemporaries. Let’s examine the strong arguments for using a three-piston air compressor in your upcoming project:

- Enhanced Power and Flow:

These compressors pack a punch with three pistons operating in tandem to produce a much higher Cubic Feet per Minute (CFM) output. This means that you can easily run more demanding pneumatic tools, such as high-pressure paint sprayers or construction projects.

- Improved Durability and Reliability:

The three-piston arrangement lessens stress on individual components by more evenly distributing the strain. This means that your compressor will last longer and require less maintenance and downtime.

- Versatility for Diverse Applications:

These compressors aren’t just for basic jobs thanks to their improved capacity and power. They are excellent in powering a greater variety of tools, such as sanders and paint sprayers for delicate woodworking jobs, as well as nail guns and impact wrenches on construction sites.

- Options for Portability:

Although three piston compressors are powerful industrial machines, some alternatives are portable. For tasks that need mobility, such as on-site jobs, these small versions provide more versatility.

In the long term, three-piston compressors may prove to be a cost-effective investment because of their greater airflow, wider range of applications, and possibly fewer maintenance requirements due to their durability.

From Construction Sites to Home Improvement: Unleashing the Potential of 3 Piston Air Compressors

These compressors are a versatile option for professionals and do-it-yourselfers alike because of their steady power, which powers a wide range of applications. Let’s examine a few of the most popular jobs that these workhorses excel at:

Construction Industry Leader:

- Impact wrenches and nail guns:

These tools make it easy to tighten bolts and drive nails with accuracy, greatly accelerating construction tasks.

- Tire Inflation:

They supply the required pressure for rapid and effective tyre inflation, whether the tyres are on delicate cars or heavy-duty construction equipment.

- Paint sprayers:

Whether painting walls, furniture, or even cars, these devices’ reliable 3 piston air compressor pressure produces finishes that appear professional.

Efficiency of Automotive Repair:

- Tire Changes:

With the ability to swiftly inflate tyres to the proper pressure, changing tyres is made simple.

- Air Wrenches:

Use the extra force of a three-piston compressor to loosen lug nuts and other difficult bolts.

- Spray guns:

For a smooth, polished finish, precisely apply primers, paints, and undercoating using this compressor.

Versatility in Woodworking:

- Brad Nailers:

Use a three-piston compressor to regulate power to create complex joinery and construct furniture quickly.

- Sanders:

A three-piston compressor’s steady air pressure will help you finish your woodworking tasks with a smooth, polished surface.

- Tools for Inflation:

For effective use, inflate sanding bags or other woodworking instruments that need compressed air.

Home Improvement Made Easy:

- Tire Inflation:

No more trips to the gas station thanks to tire inflation! With a dependable three-piston air compressor, you can quickly and simply fill your automobile tyres at home.

- Compressed Air Cleaning:

For a clean workspace, blast dust and debris from machinery, tools, and hard-to-reach places.

- Do It Yourself Paint Spraying:

A 3 piston air compressor offers enough force for do-it-yourself paint spraying operations, ranging from painting minor projects to updating furniture.

Industrial Applications:

- These compressors are a reliable choice for a variety of industrial applications. They may power sandblasting machines, cleaning equipment, and assembly line tools.

Finding Your Perfect Match: Choosing the Right 3 Piston Air Compressor

There are many alternatives available when it comes to these compressors, but choosing the best one for your needs demands careful thought. Here is a guide to help you select the compressor that will best enable your projects:

- Air Displacement (CFM):

This statistic, expressed in Cubic Feet per Minute (CFM), shows how much air a compressor can supply. Greater CFM corresponds to powering tools with higher demands. Take into account the CFM specifications of the particular tools you intend to utilize the most.

- Discharge Pressure (PSI):

The compressor’s maximum pressure output is indicated by this measurement, which is expressed in pounds per square inch (PSI). Compare the PSI to what your main tools require. Paint sprayers, for instance, require a higher PSI than nail guns.

- Duty Cycle:

The proportion of time the compressor can run continuously without overheating is indicated by this. To prevent overheating and possible damage, take into consideration a compressor with a larger duty cycle for frequent or strenuous activities.

- Tank Capacity:

Compressed air is kept in the air receiver tank for usage whenever needed. When doing jobs that call for brief bursts of high-pressure air, a larger tank acts as a buffer; for tasks that require less air continuously, a smaller tank could be adequate.

- Portability vs. Stationarity:

When agility is essential for on-site work, portable models give more freedom. Stationary variants are perfect for workshop applications because they have higher power output and larger capacity.

- Oil-Lubricated vs. Oil-Free:

Oil-lubricated compressors offer longer lifespans but require oil changes and maintenance. Oil-free compressors are maintenance-free but might have slightly lower power output.

Maintaining Your Workhorse: Crucial Upkeep Advice for Three-Piston Air Compressors

A dependable tool for taking on a variety of tasks is a well-maintained 3 piston air compressor. Through the implementation of a regular maintenance schedule, you can guarantee that your compressor operates at peak efficiency and has a longer lifespan. To maintain the smooth operation of your three-piston air compressor, follow these important maintenance tips:

- Drain Condensation Often:

If moisture builds up in the air receiver tank, it may cause corrosion and rust. To avoid these problems, empty the condensation valve located at the bottom of the tank once a day or after prolonged use.

- Replace the air filter:

A clogged filter limits airflow, which lowers efficiency and puts more strain on internal parts. As per the manufacturer’s recommended schedule, which takes into account the environment and frequency of usage, replace the air filter regularly.

- Oil Changes (Oil-Lubricated Models):

Regular oil changes are essential for compressors that use oil. As per the manufacturer’s guidelines, the oil and oil filter should be changed every 500 hours of operation or six months, whichever comes first.

- Examine and Clean Valves:

Valves can wear out or get blocked with debris over time. Make sure the intake and discharge valves are operating properly regularly. If necessary, clean or replace them. For information on certain steps, refer to the user handbook or, if necessary, seek professional advice.

- Visual Inspection:

Check hoses, belts, and other components for damage, leaks, or excessive wear. Deal with any difficulties as soon as possible to avoid more ones and guarantee safe operation.

- Keep it Clean:

To reduce the amount of dust and debris that enters the compressor and can lead to internal damage, keep the area surrounding it clean. To keep dust and filth buildup at bay, frequently wipe the compressor off with a moist cloth.

Conclusion:

3 piston air compressor provides consistent power and effectiveness. Discover the ideal compressor for woodworking, automotive, construction, and more by exploring LEIYAO Compressor wide variety.