Exploring H2 Compressor: Types, Applications, and Efficiency

Introduction

Hydrogen H2 Compressor is emerging as a key player in the transition to a more sustainable and clean energy future. It holds the potential to revolutionize various industries, from transportation to energy production. However, the efficient handling and distribution of hydrogen gas are essential for realizing its full potential. This is where H2 compressors come into play.

An H2 compressor is a specialized machine designed to increase the pressure of hydrogen gas, making it easier to transport and store. It plays a crucial role in various industrial applications and is instrumental in harnessing the power of hydrogen as a clean energy source.

Hydrogen is a versatile element with a wide range of applications. It is used in industries such as petrochemicals, metallurgy, and electronics manufacturing. Moreover, hydrogen is considered a green energy carrier, making it indispensable in the quest for a more sustainable world.

H2 compressors are the backbone of the hydrogen supply chain. They enable the compression of hydrogen gas to high pressures, allowing for efficient storage and transportation. In this comprehensive guide, we will explore the different types of H2 compressors, their applications, factors to consider when choosing one, maintenance procedures, safety measures, and future trends in H2 compressor technology.

Types of H2 Compressors

There are several types of H2 compressors available, each with its own set of advantages and applications. Let’s delve into these types:

Reciprocating H2 Compressors

1. Working Principle

Reciprocating H2 compressors operate on the principle of positive displacement. They use a piston and cylinder arrangement to compress hydrogen gas. When the piston moves, it decreases the volume within the cylinder, thus increasing the gas pressure.

2. Advantages

Reciprocating compressors are known for their high efficiency and reliability. They can handle a wide range of flow rates and are suitable for both low and high-pressure applications.

3. Applications

Reciprocating H2 compressors find applications in various industries, including hydrogen production, petrochemicals, and hydrogen fueling stations.

Rotary Screw H2 Compressors

1. Working Principle

Rotary screw H2 compressors use a pair of interlocking screws to compress hydrogen gas. As the screws rotate, they trap and compress the gas, increasing its pressure.

2. Advantages

These compressors are known for their continuous operation and relatively low maintenance requirements. They are suitable for medium to high-pressure applications.

3. Applications

Rotary screw H2 compressors are commonly used in hydrogen storage and industrial processes.

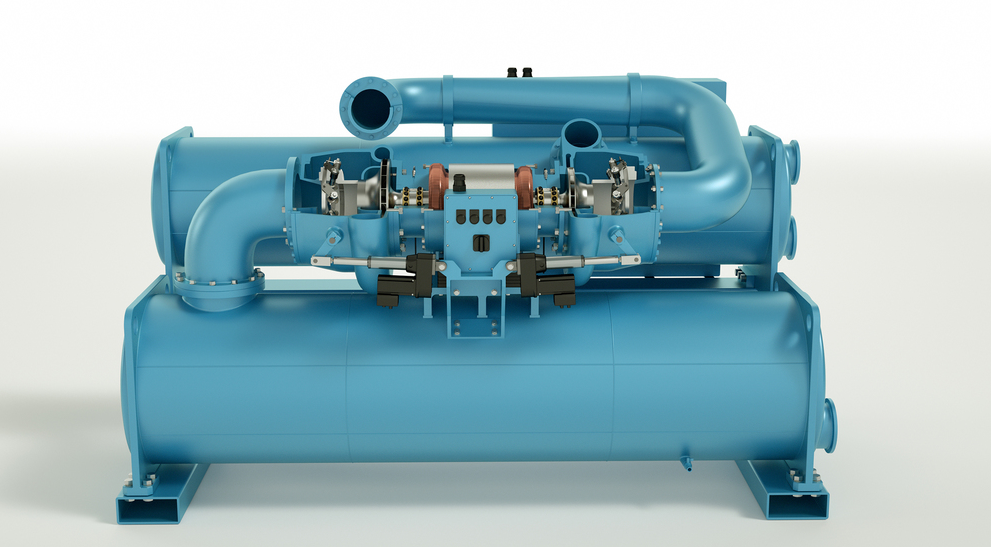

Centrifugal H2 Compressors

1. Working Principle

Centrifugal H2 compressors utilize a high-speed impeller to impart kinetic energy to the hydrogen gas. This kinetic energy is then converted into pressure as the gas is forced through a diffuser.

2. Advantages

Centrifugal compressors are known for their high flow rates and can handle large volumes of hydrogen gas. They are suitable for high-pressure applications.

3. Applications

These compressors are often used in hydrogen fueling stations and industrial processes that require large quantities of compressed hydrogen.

Applications of H2 Compressors

H2 compressors play a vital role in a wide range of applications, contributing to the growth of various industries. Let’s explore these applications in detail:

Industrial Uses

1. Hydrogen Production

H2 compressors are essential in the production of hydrogen through processes like steam methane reforming (SMR) and electrolysis. They help compress and store the produced hydrogen for various downstream applications.

2. Hydrogen Storage

Efficient hydrogen storage is crucial for industries reliant on hydrogen gas. H2 compressors ensure that hydrogen can be stored safely and economically, ready for use when needed.

3. Hydrogen Fueling Stations

As the demand for hydrogen-powered vehicles increases, the need for hydrogen fueling stations grows as well. H2 compressors enable the rapid refueling of these vehicles, making hydrogen a practical choice for transportation.

Renewable Energy Sector

1. Hydrogen as an Energy Carrier

Hydrogen serves as a valuable energy carrier, storing excess energy generated from renewable sources like wind and solar. H2 compressors play a pivotal role in converting electrical energy into hydrogen gas and vice versa when needed.

2. Hydrogen-Powered Vehicles

Fuel cell vehicles are gaining traction as an eco-friendly alternative to traditional gasoline vehicles. H2 compressors ensure the efficient refueling of these vehicles, promoting clean transportation.

3. Fuel Cell Applications

Fuel cells are used to generate electricity from hydrogen gas, and H2 compressors are essential for providing the high-pressure hydrogen required for these cells to function efficiently.

Factors to Consider When Choosing an H2 Compressor

Selecting the right H2 compressor for your specific application is crucial. Here are some key factors to consider:

A. Capacity and Flow Rate Requirements

Determine the volume of hydrogen gas you need to compress and the required flow rate. Different compressors have varying capacities, so choose one that matches your needs.

B. Energy Efficiency and Environmental Considerations

Opt for compressors that are energy-efficient to reduce operational costs and minimize your carbon footprint. Look for models that meet environmental standards and regulations.

C. Safety Features

Hydrogen is flammable and requires special safety precautions. Ensure that the compressor you choose has robust safety features, including leak detection and emergency shutdown systems.

D. Maintenance and Serviceability

Consider the ease of maintenance and availability of spare parts. Regular maintenance is essential for the long-term performance of your H2 compressor.

Maintenance and Care of H2 Compressors

Maintaining your H2 compressor is vital for its longevity and optimal performance. Here are some maintenance guidelines to follow:

A. Importance of Regular Maintenance

Regular maintenance prevents breakdowns and ensures that your compressor operates efficiently, reducing downtime and repair costs.

B. Recommended Maintenance Tasks and Schedules

Follow the manufacturer’s recommended maintenance schedule, which typically includes tasks like lubrication, filter replacement, and inspection of critical components.

C. Tips for Ensuring Longevity and Optimal Performance

Implement best practices, such as keeping the compressor clean, monitoring performance, and addressing any issues promptly, to extend the life of your H2 compressor.

H2 Compressor Safety Measures

Safety is paramount when dealing with hydrogen gas. Here are essential safety measures to adhere to:

A. Safety Precautions for Handling Hydrogen

Follow strict safety protocols when handling, storing, and transporting hydrogen gas. This includes proper ventilation, fire prevention measures, and protective equipment.

B. Ventilation and Gas Detection

Ensure adequate ventilation in areas where hydrogen is present, and use gas detection systems to monitor for leaks and maintain safe hydrogen concentrations.

C. Emergency Procedures and Training

Train personnel on emergency procedures, including how to respond to hydrogen leaks or accidents. Preparedness can prevent accidents from escalating.

Future Trends in H2 Compressor Technology

The field of H2 compressor technology is continually evolving to meet the growing demand for hydrogen-based applications. Here are some future trends to watch out for:

A. Advancements in Efficiency and Energy Savings

Researchers and engineers are working on improving the efficiency of H2 compressors, reducing energy consumption and operational costs.

B. Smart Monitoring Systems for Improved Performance

The integration of smart sensors and monitoring systems allows for real-time performance tracking and predictive maintenance, enhancing reliability and reducing downtime.

C. Sustainable Practices in Hydrogen Compression

As sustainability becomes a focal point, there is a growing emphasis on developing eco-friendly and energy-efficient compression technologies that align with clean energy goals.

Conclusion

In conclusion, H2 compressors play a pivotal role in the efficient handling and distribution of hydrogen gas across various industries. They are instrumental in realizing the full potential of hydrogen as a clean energy source and energy carrier. By considering factors such as capacity, energy efficiency, safety features, and maintenance, businesses can make informed decisions when choosing H2 compressors. As technology continues to advance, the future of H2 compressor technology holds the promise of greater efficiency and sustainability, further driving the adoption of hydrogen in our quest for a greener and cleaner world. Embrace the potential of H2 compressors and join the journey towards a more sustainable future powered by hydrogen.