Exploring CNG Compressor: A Comprehensive Guide

In today’s world, where environmental sustainability and clean energy solutions are of paramount importance, Compressed Natural Gas (CNG) has emerged as a game-changer. At the heart of the CNG ecosystem are CNG compressors, essential devices that enable the efficient pressurization of natural gas for various applications. In this comprehensive guide, we will delve into the world of CNG compressors, from their definition and importance to their diverse applications and future prospects.

Introduction to CNG Compressor

A. Definition of CNG Compressor

A CNG compressor, or Compressed Natural Gas compressor, is a specialized machine designed to elevate the pressure of natural gas, transforming it into a usable and transportable fuel. It is a pivotal component of the CNG infrastructure, ensuring that natural gas can be effectively utilized in various sectors, including transportation, industry, and more.

B. Importance of CNG Compressor

The significance of CNG compressors cannot be overstated. They are the backbone of the CNG industry, making it possible to store, transport, and distribute natural gas efficiently. This importance lies in their role in reducing carbon emissions, promoting cleaner energy solutions, and contributing to a greener planet.

Application Areas of CNG Compressors

CNG compressors find diverse applications across several sectors:

- Natural Gas Vehicles (NGVs): CNG compressors are instrumental in fueling NGVs, which are becoming increasingly popular as a cleaner alternative to traditional gasoline and diesel vehicles.

- Fueling Stations: CNG fueling stations rely on these compressors to provide a convenient and accessible refueling infrastructure for NGV users.

- Industrial and Commercial Use: Industries and businesses utilize CNG compressors for manufacturing processes, power generation, and more, reaping the benefits of clean energy.

Types of CNG Compressor

CNG compressors come in various types, each with its own working principle, advantages, and disadvantages:

A. Reciprocating CNG Compressors

- Working Principle: Reciprocating CNG compressors operate using a piston-cylinder mechanism, where the piston compresses the gas. This compression process elevates the gas pressure, making it suitable for various applications.

- Advantages and Disadvantages: These compressors offer high efficiency but can be noisy and require more maintenance compared to other types.

B. Rotary Screw CNG Compressors

- Working Principle: Rotary screw CNG compressors use rotating screws to compress the gas. As the screws rotate, they reduce the volume of the gas, increasing its pressure.

- Advantages and Disadvantages: They are known for their reliability and quiet operation, although they may have higher initial costs compared to reciprocating compressors.

C. Centrifugal CNG Compressors

- Working Principle: Centrifugal CNG compressors use centrifugal force to compress gas. The gas enters a rotating impeller, and the centrifugal force generated by the impeller’s rotation compresses the gas.

- Advantages and Disadvantages: These compressors are energy-efficient but may not be suitable for all applications due to their specific operating requirements.

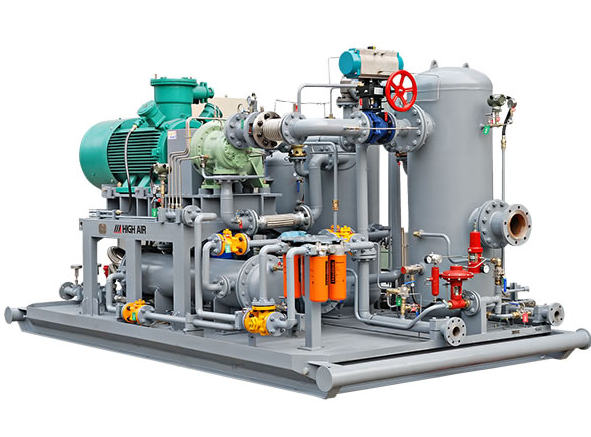

Key Components of CNG Compressors

Understanding the key components of CNG compressors is essential to grasp how they function:

A. Compressor Unit

The compressor unit is the core of a CNG compressor. It houses the mechanisms responsible for compressing natural gas to the desired pressure levels.

B. Cooling System

To prevent overheating during operation, CNG compressors are equipped with cooling systems that regulate their temperature.

C. Control System

The control system manages the compressor’s operation, ensuring it functions optimally and safely.

D. Safety Features

Safety features are crucial in CNG compressors to prevent accidents and ensure the secure operation of the equipment.

Applications of CNG Compressors

CNG compressors play a pivotal role in several practical applications:

A. Natural Gas Vehicles (NGVs)

NGVs are increasingly popular due to their lower carbon emissions. CNG compressors enable the refueling of these vehicles, contributing to cleaner transportation.

B. Fueling Stations

CNG fueling stations are vital for the widespread adoption of NGVs. CNG compressors provide the necessary infrastructure for refueling, promoting the use of natural gas as a fuel source.

C. Industrial and Commercial Use

Industries and commercial enterprises utilize CNG compressors for various purposes, from powering machinery to providing clean energy for industrial processes.

Benefits of CNG Compressors

The advantages of CNG compressors extend beyond just efficient fueling:

A. Environmental Benefits

CNG is a cleaner-burning fuel, resulting in reduced emissions of harmful pollutants and greenhouse gases. This reduction in environmental impact contributes to a greener and healthier planet.

B. Economic Benefits

CNG is often more cost-effective than traditional fuels, leading to potential savings for both businesses and consumers. Additionally, it can reduce dependence on imported oil.

C. Energy Efficiency

CNG compressors are designed for energy efficiency, maximizing the utilization of natural gas resources and reducing waste.

Maintenance and Safety Considerations

A. Routine Maintenance

Regular maintenance is crucial to ensure the continued performance and longevity of CNG compressors. Routine checks, lubrication, and inspections are essential.

B. Safety Precautions

Safety is paramount when dealing with CNG compressors. Proper training, equipment checks, and adherence to safety protocols are essential to prevent accidents.

C. Compliance with Regulations

CNG compressors must comply with local regulations and safety standards to ensure their safe operation.

Future Trends in CNG Compressor Technology

The world of CNG compressors is constantly evolving. Here are some future trends to watch for:

A. Advancements in Compressor Design

Continuous innovations in compressor design aim to improve efficiency, reduce maintenance requirements, and enhance overall performance.

B. Integration with Renewable Energy Sources

The integration of CNG compressors with renewable energy sources, such as solar and wind power, is on the horizon. This could further reduce the carbon footprint of CNG compression.

C. Potential for Fuel Cell Vehicles

CNG may play a role in the development of fuel cell vehicles, offering a clean and efficient energy source for these innovative vehicles.

Manufacturers and Suppliers of CNG Compressors

To navigate the world of CNG compressors, it’s essential to know the key players:

A. Prominent CNG Compressor Manufacturers

Several manufacturers specialize in producing high-quality CNG compressors. Understanding their offerings can help you make informed decisions.

B. Global Suppliers and Distributors

Global suppliers and distributors ensure the availability of CNG compressors in various regions, promoting their widespread use.

C. Customer Reviews and Ratings

Customer feedback and reviews can provide valuable insights into the performance and reliability of different CNG compressors.

Factors to Consider When Choosing a CNG Compressor

Selecting the right CNG compressor requires careful consideration of various factors:

A. Capacity and Flow Rate

The compressor’s capacity and flow rate should match the requirements of your specific application.

B. Energy Efficiency and Operating Costs

Evaluate the compressor’s energy efficiency to optimize operating costs over time.

C. Reliability and Durability

Reliability and durability are crucial for minimizing downtime and maintenance costs.

D. Maintenance Requirements

Consider the maintenance requirements of the compressor and whether they align with your operational capabilities.

E. Compliance with Local Regulations

Ensure that the chosen compressor complies with local regulations and safety standards.

Installation and Setup of CNG Compressors

Proper installation and setup are essential for the safe and efficient operation of CNG compressors:

A. Site Selection and Preparation

Choosing an appropriate site and preparing it for compressor installation is the initial step in the process.

B. Proper Installation Procedures

Following correct installation procedures is vital to ensure the compressor operates as intended.

C. Testing and Commissioning

Comprehensive testing and commissioning processes help verify the compressor’s functionality and safety.

Case Studies and Success Stories

Real-world examples highlight the impact of CNG compressors:

A. Real-world Examples of CNG Compressor Installations

Explore instances where CNG compressors have been successfully implemented, showcasing their practical applications.

B. Impact on Reducing Carbon Emissions

Case studies can demonstrate how the use of CNG compressors contributes to significant reductions in carbon emissions.

C. Cost Savings and ROI for Businesses

Business success stories illustrate how CNG compressors can lead to substantial cost savings and a positive return on investment.

Challenges and Limitations of CNG Compressors

Despite their numerous advantages, CNG compressors face challenges and limitations:

A. Infrastructure Development Challenges

The expansion of CNG infrastructure, including refueling stations, can be hindered by logistical and investment challenges.

B. Limited Availability of CNG Stations

The availability of CNG fueling stations may be limited in some regions, affecting the convenience of using NGVs.

C. Safety Concerns and Accidents

Safety concerns, including gas leaks and accidents, must be addressed to ensure the secure operation of CNG compressors.

Government Incentives and Policies

Government support plays a crucial role in the growth of the CNG industry:

A. Government Support for CNG Infrastructure

Government initiatives aimed at promoting CNG infrastructure development are instrumental in driving adoption.

B. Tax Credits and Incentives for CNG Vehicle Adoption

Tax credits and incentives can encourage consumers and businesses to adopt CNG vehicles, further reducing their environmental impact.

C. Environmental Regulations and Compliance

Stringent environmental regulations may require businesses to transition to cleaner fuels, such as CNG, driving the demand for CNG compressors.

International Perspectives on CNG Compressor

CNG usage and trends vary across different countries and regions:

A. CNG Usage and Trends in Different Countries

Explore how various countries are embracing CNG as a clean transportation and energy solution.

B. Global Efforts to Promote Clean Transportation

International collaborations and agreements aim to promote the adoption of clean transportation technologies, including CNG.

Conclusion

A. Recap of CNG Compressor Significance

CNG compressors play a pivotal role in the transition to cleaner energy solutions, reducing carbon emissions, and promoting economic benefits.

B. Encouraging Sustainable Transportation and Energy Solutions

By choosing CNG as a fuel source and investing in CNG compressors, individuals and businesses can contribute to a more sustainable and environmentally friendly future.

C. Future Growth Prospects for the CNG Compressor Industry

As technology advances and environmental awareness grows, the CNG compressor industry is poised for continued growth and innovation.

In conclusion, CNG compressors are integral to the promotion of cleaner energy solutions and the reduction of greenhouse gas emissions. Understanding their working principles, applications, benefits, and challenges is essential for individuals and businesses looking to embrace eco-friendly transportation and energy alternatives. As we move forward, advancements in CNG compressor technology and supportive government policies are expected to drive the widespread adoption of CNG as a cleaner and more sustainable fuel source.