Optimizing LNG Operations: The Essential Role of BOG Compressors

LNG (Liquefied Natural Gas) bog compressors play a pivotal role in the energy sector by addressing a critical challenge: Boil-Off Gas (BOG). BOG is formed during the storage and transportation of LNG when ambient heat causes a portion of the LNG to vaporize. This gas must be managed to prevent wastage and maintain the integrity of LNG infrastructure. Bog compressors are the key to re-liquefying BOG, ensuring efficient storage, reducing emissions, and enhancing the viability of LNG as a clean and portable energy source.

Understanding BOG (Boil-Off Gas)

Definition and Formation of BOG

Boil-off gas (BOG) constitutes the gaseous fraction of Liquefied Natural Gas (LNG) that emerges when LNG is subjected to higher temperatures, often during storage and transportation. While LNG is carefully kept at ultra-low temperatures to maintain its liquid form, some of it inevitably transforms into BOG due to heat exposure.

Challenges Posed By BOG in LNG Operations

BOG presents substantial challenges in LNG operations. Firstly, it signifies the loss of valuable LNG, diminishing the overall efficiency and financial viability of LNG infrastructure. Furthermore, BOG accumulation can result in heightened pressure levels within storage tanks, potentially leading to safety hazards if not properly managed. Additionally, BOG consists primarily of methane, a potent greenhouse gas, amplifying environmental concerns and regulatory compliance issues. To address these challenges effectively, the implementation of compression and re-liquefaction processes is imperative for BOG management, offering a means to alleviate economic losses and curtail the environmental impact of LNG operations.

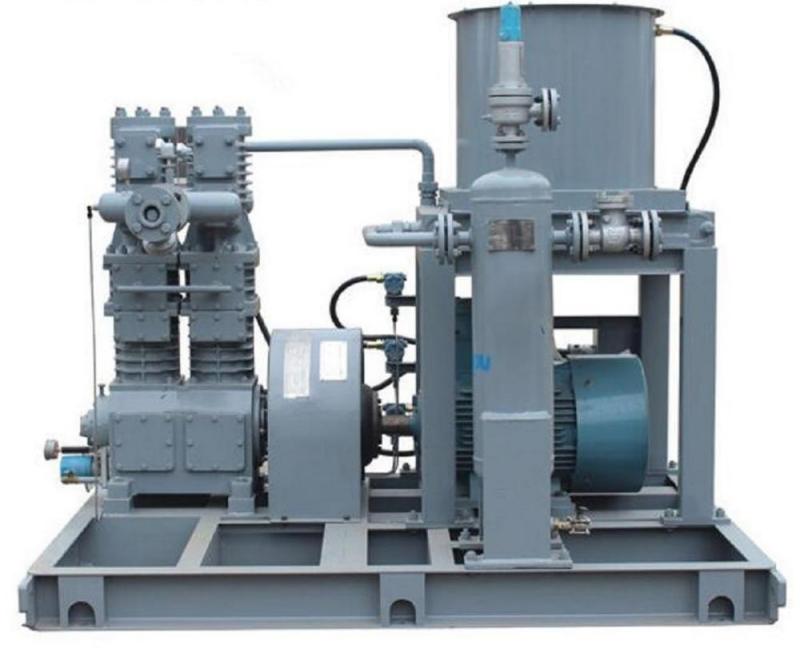

BOG Compressor: The Solution

Basic Functionality and Purpose

BOG compressors are pivotal tools within LNG (Liquefied Natural Gas) operations, strategically devised to tackle the issues arising from Boil-Off Gas (BOG). These compressors perform a dual function encompassing compression and re-liquefaction.

How Do They Mitigate the Challenges Posed by BOG?

Primarily, BOG compressors operate by elevating the pressure of the gaseous BOG, thereby augmenting its density and diminishing its volume. This compression process facilitates the transformation of BOG into its liquid form, allowing for its reintroduction into LNG storage tanks or utilization as fuel, circumventing unnecessary emissions into the atmosphere.

Secondarily, BOG compressors adeptly confront the multifaceted challenges posed by BOG. They proficiently oversee BOG, averting its unproductive venting and curtailing financial losses. Simultaneously, through re-liquefaction, these compressors sustain optimal pressure levels within LNG storage tanks, ensuring operational security and reliability. Beyond these operational aspects, BOG compressors play a pivotal role in the eco-conscious dimension of LNG operations by capturing and repurposing BOG rich in methane, a potent greenhouse gas, thus promoting environmental compliance and harmonizing with sustainability objectives and regulatory mandates.

Advantages of Using BOG Compressors in LNG Operations

Employing BOG compressors in LNG (Liquefied Natural Gas) operations confers a host of advantages:

Enhanced Storage Efficiency

BOG compressors efficiently re-liquefy gaseous Boil-Off Gas (BOG), averting wastage. This optimization augments LNG storage capacity, curbing losses, and maximizing the utilization of valuable LNG reserves.

Reduced Greenhouse Gas Emissions

By capturing and recycling BOG, these compressors curb the release of methane, a potent greenhouse gas, into the environment. This substantial reduction aligns LNG operations with environmental sustainability objectives and regulatory compliance.

Enhanced Safety

BOG compressors are pivotal in maintaining safe pressure levels within LNG storage tanks, forestalling over-pressurization and potential safety risks. This bolsters the overall safety of LNG handling and transport, safeguarding personnel and infrastructure.

Economic Advantages

The effective BOG management facilitated by compressors translates to diminished economic losses. It permits the retrieval and repurposing of BOG as fuel or for other applications, not only economizing costs but also fortifying the economic viability of LNG as an energy source.

Technological Advancements in BOG Compressors

Recent technological advancements in BOG (Boil-Off Gas) compressors have revolutionized LNG (Liquefied Natural Gas) operations, bringing significant benefits to the industry:

Modern Design Enhancements

Contemporary BOG compressors feature advanced design improvements. These include optimized compression stages and materials, resulting in greater efficiency and durability. Enhanced rotor dynamics and aerodynamics ensure smoother operation, reducing wear and tear on components. Furthermore, improved sealing technologies minimize leakage and enhance overall performance, contributing to a longer compressor lifespan.

Integration of Automation and AI for Predictive Maintenance

Automation and Artificial Intelligence (AI) have been integrated into BOG compressor systems. AI algorithms analyze real-time data from sensors and operational parameters, predicting maintenance needs accurately. This proactive approach reduces downtime, lowers maintenance costs, and maximizes the operational lifespan of compressors. Additionally, automated control systems can optimize compressor operation in response to changing conditions, ensuring efficiency and reliability.

Energy Efficiency Improvements

Efficiency is a key focus in BOG compressor advancements. Variable speed drives and advanced control strategies allow compressors to adapt their output to demand, reducing energy consumption during periods of lower BOG generation. Additionally, innovative heat recovery systems capture and reuse excess heat generated during compression, increasing overall energy efficiency. These enhancements not only reduce operational costs but also contribute to a greener and more sustainable LNG industry.

Technological advancements in BOG compressors are driving efficiency, reliability, and sustainability in LNG operations. These modern designs, AI-driven predictive maintenance, and energy-efficient solutions are helping the industry optimize its resources and reduce environmental impact, making LNG a more competitive and environmentally friendly energy source.

LNG BOG Compressors: Powering the Future of Sustainable LNG Operations

In the quest for more efficient, environmentally responsible, and economically viable LNG (Liquefied Natural Gas) operations, BOG (Boil-Off Gas) compressors stand as indispensable assets. These remarkable technologies, with their modern design enhancements, integration of automation and AI for predictive maintenance, and energy efficiency improvements, play a pivotal role in optimizing LNG operations.

BOG compressors not only re-liquefy and reclaim valuable LNG resources but also reduce greenhouse gas emissions and enhance safety. They are the linchpin in maintaining optimal storage conditions, safeguarding infrastructure, and aligning LNG operations with stringent environmental standards.

As the global energy landscape evolves, BOG compressors continue to drive progress, enabling the LNG industry to meet the growing demand for clean energy while minimizing waste and maximizing efficiency. Their transformative capabilities underscore their essential role in shaping the future of LNG operations, forging a path toward a more sustainable and responsible energy future.