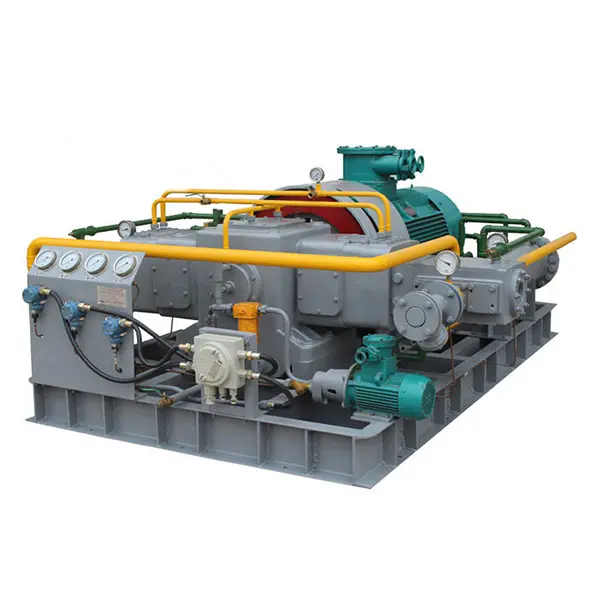

Nitrogen Compressor

Nitrogen Compressor

- Brand: Huayan Gas

- Place of Origin: China·Xuzhou

- Compressor structure: Piston Compressor

- Volume flow: 3NM3/hour~1000NM3/hour (customized)

- Voltage: 380V/50Hz (customized)

- Maximum outlet pressure: 100MPa (customized)

Get Free Quote

Description

Our company specializes in producing nitrogen compressor, representing our flagship product line known for its advanced technology and exceptional stability. Our nitrogen compressors primarily consist of large and medium-sized natural gas compressors. These compressors cover various exhaust pressures, from 0.1MPa to 25.0MPa, and offer displacement options from 0.05m3/min to 20m3/min. With a commitment to delivering reliable and efficient solutions, our nitrogen compressors are designed to meet the demands of various industrial applications.

Features & Characteristics:

Key Features and Performance Highlights:

- Long Service Life: Our nitrogen compressors are built to last, featuring robust construction and high-quality materials. This ensures a prolonged service life, providing users with a durable and reliable solution for their nitrogen compression needs.

- Sufficient Gas Volume: Engineered for optimal performance, our compressors deliver ample gas volume to meet the requirements of diverse applications. Whether for industrial processes or specialized uses, our compressors consistently provide the necessary gas volume efficiently.

- Convenient Maintenance: We understand the importance of easy maintenance to minimize downtime. Our nitrogen compressors are designed with user-friendly maintenance features, making routine servicing and repairs straightforward. This ensures that your equipment remains in peak condition with minimal disruption to your operations.

- High Stability: Our nitrogen compressors are engineered for stability, ensuring consistent and reliable performance even under demanding operating conditions. This high stability is a testament to the precision engineering and quality control embedded in our compressor design.

- Energy Efficiency: Focusing on sustainability, our compressors are designed to maximize energy efficiency. This reduces operational costs and contributes to environmental conservation by minimizing energy consumption.

Main Structure: Nitrogen Compressor

- The core of the nitrogen compressor is the compressor body, which houses the essential components responsible for gas compression.

- Constructed from high-quality materials, the compressor body is designed to withstand the pressures and forces associated with the compression process.

- The compression of nitrogen is achieved through a cylinder and piston assembly. This critical component facilitates nitrogen gas intake, compression, and discharge.

- The materials used in constructing the cylinders and pistons are chosen for their durability and resistance to wear.

- The drive system powers the compressor and maintains a consistent and reliable compression process.

- It typically includes an electric motor or an internal combustion engine, along with a transmission system, to drive the movement of the pistons.

- A cooling system is integrated into the structure to manage the heat generated during compression.

- The control panel houses the advanced control systems that govern the operation of the nitrogen compressor.

Applications: Nitrogen Compressor

- Nitrogen Pressurization at the Rear End of Nitrogen Generators: Nitrogen compressors are employed to boost the pressure of the nitrogen generated, ensuring it meets the specific requirements of downstream applications. This is crucial for applications where nitrogen at higher pressures is necessary, such as in the oil and gas industry or certain manufacturing processes.

- Nitrogen Replacement in Chemical Plants and Gas Units: Nitrogen compressors supply compressed nitrogen for purging or replacing gases in reactors, pipelines, and other equipment. This ensures a controlled and inert atmosphere, preventing undesired chemical reactions and maintaining the integrity of processes.

- Nitrogen Filling Bottles: Nitrogen compressors fill bottles with compressed nitrogen, creating a protective environment that prevents oxidation and degradation of sensitive products. This is particularly important in preserving beverages, pharmaceuticals, and electronic components.

- Nitrogen Injection Wells: Nitrogen compressors supply the high-pressure nitrogen required for injection wells. This injected nitrogen helps displace oil, reduce viscosity, and maintain reservoir pressure, leading to increased oil production.

| Partial nitrogen piston compressor product specifications | ||||||

| Model | Flow-rate

(Nm³/h) |

Intake pressure

(MPa) |

Exhaust pressure

(MPa) |

Rotating speed

(Rpm) |

Motor Power

(Kw) |

|

| 1 | ZW-0.6/2-25 | 90 | 0.2 | 2.5 | 740 | 30 |

| 2 | ZW-1.5/1-12 | 180 | 0.1 | 1.2 | 730 | 22 |

| 3 | ZW-1.4/2-40 | 250 | 0.2 | 4 | 740 | 37 |

| 4 | ZW-1.3/4-25 | 340 | 0.4 | 2.5 | 980 | 37 |

| 5 | VW-7.2/2.5-6 | 1200 | 0.25 | 0.6 | 980 | 45 |

| 6 | VW-15/0.5-3 | 1200 | 0.05 | 0.3 | 980 | 75 |

| 7 | VW-9.7/1-10 | 1100 | 0.1 | 1.0 | 985 | 110 |

| 8 | VW-7.2/1-22 | 800 | 0.1 | 2.2 | 985 | 132 |

| 9 | DW-1.2/2-150 | 400 | 0.2 | 15 | 740 | 45 |

| 10 | DW-0.5/20-160 | 600 | 2.0 | 16 | 740 | 75 |

| 11 | DW-3.8/10-45 | 2300 | 1.0 | 4.5 | 740 | 185 |

| 12 | DW-11/4-20 | 3000 | 0.4 | 2.0 | 740 | 250 |