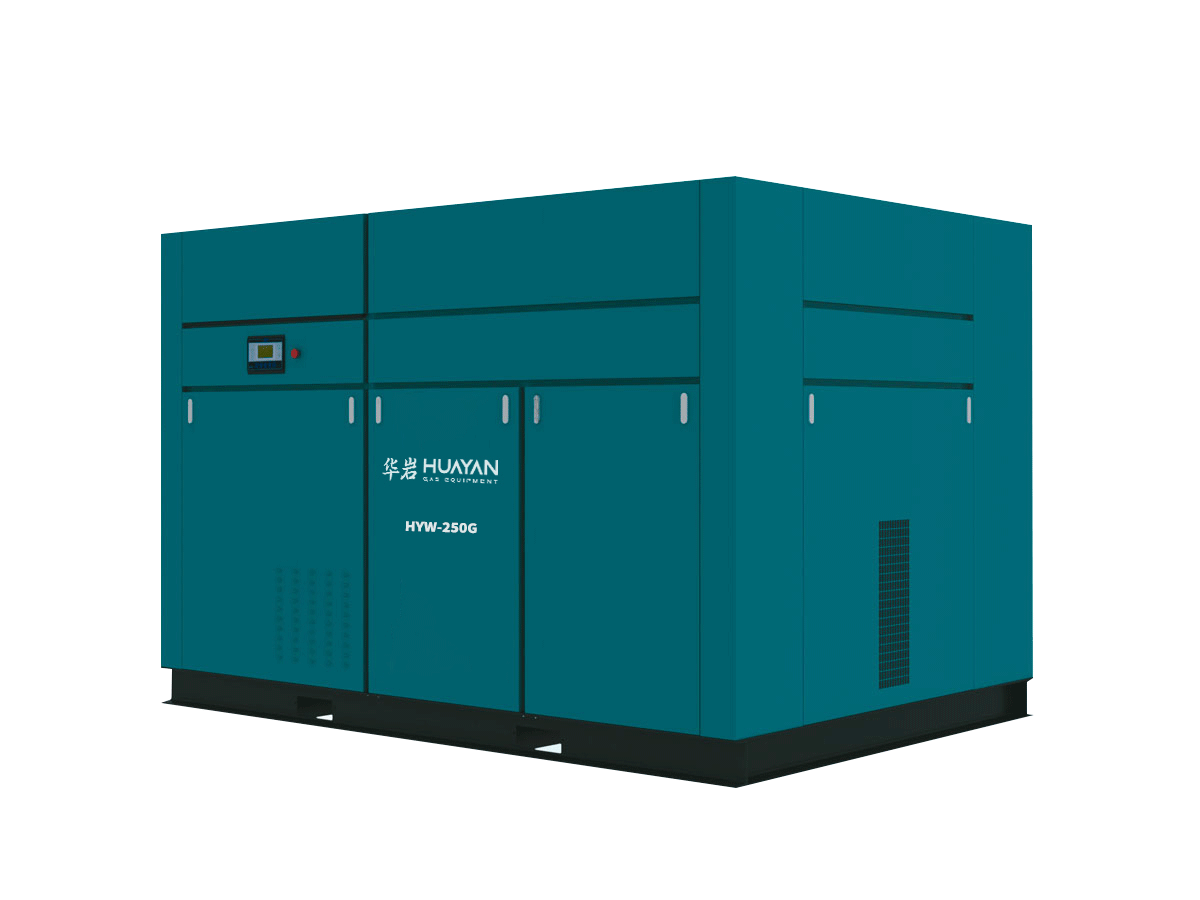

Permanent Magnet Variable Frequency Screw Compressor, Oil-Free

Permanent Magnet Variable Frequency Screw Compressor, Oil-Free

- Power 7.5-250kw

- Voltage 380V 3phase

- Working Pressure 7-13bar

- Flow 1m³-38m³/min

- Start Method Frequency Conversion Start

- Material Stainless Steel

Description

An oil-free permanent magnet variable frequency screw compressor is a type of air compressor that combines several advanced technologies to provide efficient and reliable compressed air without the use of lubricating oil.

Features & Characteristics:

Here are some key features and benefits of an Oil-free permanent magnet variable frequency screw compressor:

Eco-Friendly Construction: Crafted from high-quality raw materials, our screw compressor prioritizes safety and environmental responsibility. With a commitment to sustainability, it ensures a clean and green operation without compromising on performance.

Original Motor for Environmental Compliance: The screw compressor boasts an original motor that not only delivers exceptional performance. This innovation ensures efficiency without compromising on eco-friendliness.

Low Noise Design and Minimal Maintenance: Our compressor focuses on user comfort, featuring a low-noise design that minimizes operational disturbances. The low maintenance cost also guarantees a hassle-free and cost-effective solution for your compressed air needs.

Intelligent Variable Frequency Technology: Incorporating intelligent variable frequency technology, our compressor adapts seamlessly to varying demands, optimizing energy consumption and providing unmatched efficiency.

Remote Monitoring Capability: Stay in control with the remote monitoring capability, allowing users to track performance metrics, receive alerts, and troubleshoot issues from a distance for enhanced convenience.

Energy-Efficient Air End Design: The air end design is optimized for energy efficiency, maximizing the conversion of power to compressed air and reducing overall energy consumption.

Main Structure: variable frequency screw compressor

Our Oil-free permanent magnet variable frequency screw compressor main structure.

- Large diameter and low speed for reduced noise levels, creating a tranquil working environment.

- Accommodates both parallel shaft dynamics and cross shaft dynamics.

- Provides flexibility to meet diverse operational requirements.

- Robust metal frame with a resilient rubber ring for effective high-pressure operation.

- Maintains lubrication status, ensuring optimal performance.

- Axial seal ring, processed with patented technology, offers perfect sealing characteristics and an extended service life.

- System design optimization by technical experts.

- Lower operating failure rate compared to industry leaders.

Applications: variable frequency screw compressor

Here are potential applications for the described Oil-free permanent magnet variable frequency screw compressor with its highlighted features:

- Mining and Construction: In mining and construction, oil-free compressors are used for various tasks, such as operating pneumatic tools, cleaning, and powering equipment. The absence of oil ensures that the compressed air does not adversely affect the surrounding environment.

- Plastics Industry: Plastics manufacturing processes often involve using compressed air for tasks like material conveying, blow moulding, and pneumatic controls. Oil-free compressors are essential to prevent contamination of plastic products.

- Printing Industry: In printing operations, such as those in the packaging and publishing sectors, compressed air is used for tasks like powering printing presses and pneumatic controls. Oil-free compressors are critical to avoid contaminating printed materials.

- HVAC Systems: Heating, ventilation, and air conditioning (HVAC) systems use compressed air for various functions. Oil-free compressors are suitable for applications where air quality is a primary concern.

- Rail and Transportation: In the rail and transportation industry, oil-free compressors are used for braking systems, pneumatic controls, and maintenance operations to ensure the safety and reliability of the transportation infrastructure.